Introduction

Scaffolding is a key component in construction, providing workers with secure access to elevated regions. But bad scaffolding can cause accidents, injuries, and even deaths. GOWE uses strict safety precautions throughout the manufacturing process to avoid these kinds of problems. The company makes sure that every scaffold product satisfies and goes above and above international safety regulations.

This article talks about how GOWE makes sure that scaffolding is safe by testing the materials, controlling the quality, following global standards, and making things better all the time.

Strict testing of raw materials

The quality of the basic materials used to make a scaffold is what makes it safe. GOWE does a lot of testing on scaffolding materials, such as:

- Chemical composition analysis ensures that the steel meets the necessary standards.

- Tests of physical and mechanical properties check tensile strength, yield strength, and elongation to make sure the material is strong.

We test materials in accordance with BS1139, EN39, EN10219, ASTM A500, and ASTM A36 to ensure their compliance with international standards.

If any materials fail these tests, they are promptly thrown out. This stops weak or broken parts from being used in production.

Testing of scaffold parts and accessories

Scaffolding safety depends not only on the main structure but also on accessories and connecting elements. GOWE guarantees every part satisfies safety requirements through:

- Shearing and loading tests check the strength of joints, clamps, and couplers.

- Tests for hardness and bending make sure that accessories can handle force without changing shape.

Only parts that are fully qualified go on to assembly, which lowers the danger of structural failure.

Welding Quality Assurance

Weak welds can make scaffolding less safe. GOWE observes rigorous rules for welding:

- ISO 3834 and EN1090 Compliance—Makes sure that welding methods satisfy high standards of quality.

- Penetration Testing—Conducts sampling inspections at every welding stage to uncover faults.

This careful method stops weld fractures, porosity, and incomplete fusion, which keeps the structure stable for a long time.

Quality Management System (ISO 9001)

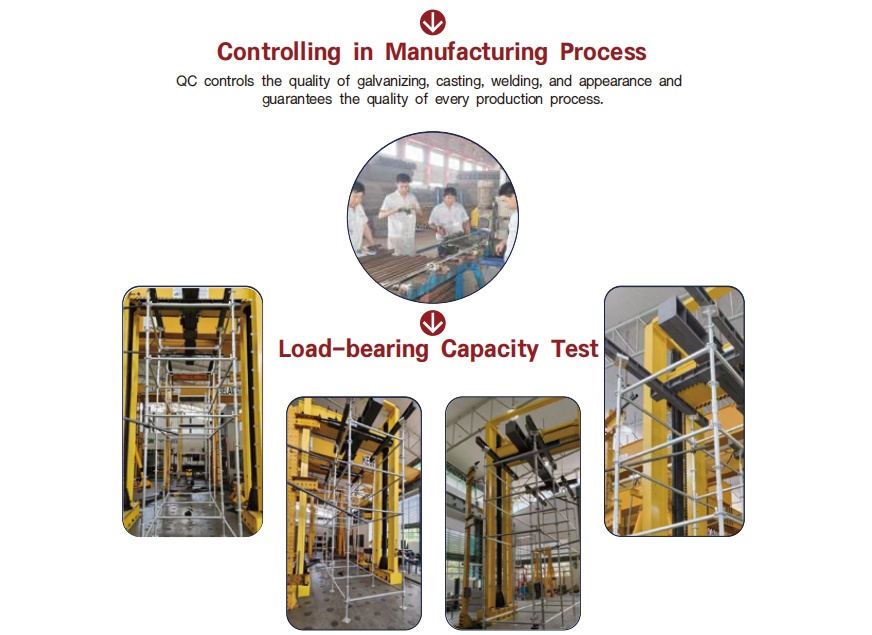

GOWE follows the ISO 9001 Quality Management System, which has tight controls at every stage of production:

- Checks for dimensional accuracy: make sure that all the parts fit together precisely.

- Marking and documentation Keep track of every part so that it can be traced.

The processes of inspection and filing maintain detailed records to ensure accountability. This methodical methodology makes sure that every scaffold product is of the same high quality.

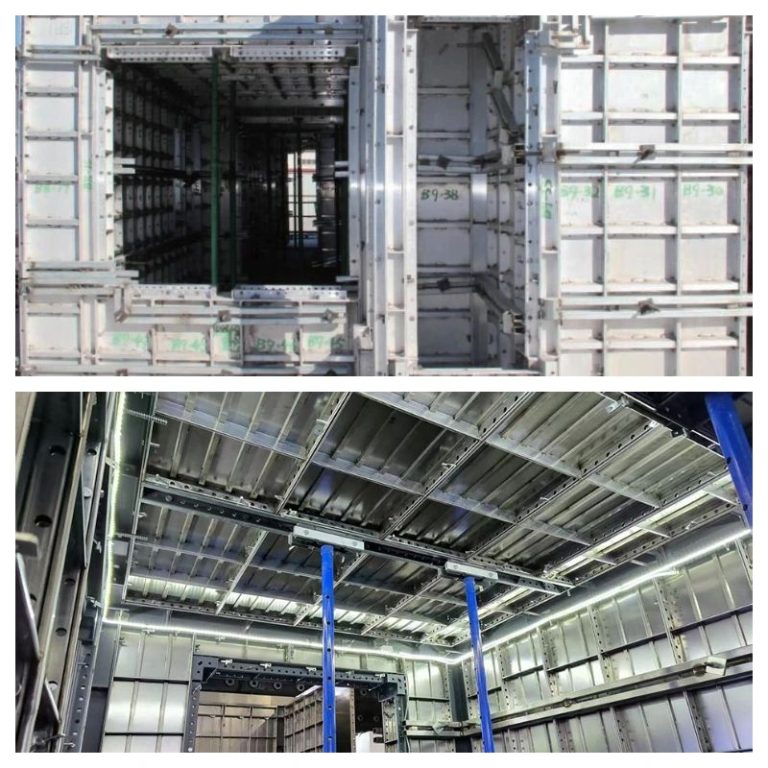

System scaffolding Mock-Up Inspections

Before making many products, GOWE does mock-up inspections to make sure:

- Component Compatibility—Ensures parts fit securely. The product must be easy to assemble, ensuring a swift and safe installation process.

- Structural Safety—Checks how stable and strong the structure is. This stage avoids design mistakes that could cause mishaps on the job site.

Testing for galvanizing and corrosion resistance

Scaffolds are outside in bad weather; thus, they need to be able to withstand corrosion. GOWE does:

- Zinc Thickness Inspection: Makes sure that ISO1461 and EN 12811 are followed.

- Adhesion Tests Check to see if the galvanized coating sticks well to the steel.

These Following these steps will make the scaffold last longer and prevent it from breaking down due to rust.

Following Global Scaffolding Standards

GOWE keeps up with international rules for scaffolding, such as

- European Scaffolding Standards EN12810

- Standards from OSHA (U.S. Occupational Safety Requirements)

Ultimate Load Capacity Tests make sure that scaffolds can safely hold the most weight.

GOWE promises safety and reliability that can’t be beat by going above and beyond these criteria.

Ongoing training and improvement

GOWE spends money on training their employees on a regular basis to make sure that they:

- Know what safety rules apply around the world.

- Learn how to put things together and check them properly.

- Stay up to date on new rules in your field.

Also, input from customers helps the company keep getting better by making goods that work better.

In conclusion

Safety on scaffolding is a must in construction. GOWE’s multi-layered quality control checks everything from the materials used to the welding to make sure that every scaffold is strong, safe, and won’t break. When you choose GOWE scaffolding, you are investing in safety, quality, and following the strictest rules in the world.

📞 Get in touch with us today for a free quote! Let’s work together to make construction sites safer.