What is formwork in slab construction? A Practical Guide for Builders Who Are Having Trouble with Slab Construction? This Is Why Formwork Is So Important.

Formwork for slabs is an important part of building with concrete. Formwork has a big impact on the strength, stability, and finish of any concrete slab, whether you’re building residences, corporate complexes, or industrial buildings.

Without strong formwork, it becomes nearly impossible to achieve the correct dimensions, ensure the structure can support new concrete loads, and provide the best surface finishes required by modern standards. In many projects, changes to formwork can change the cost of building a slab by as much as 30%.

This tutorial explains what slab formwork is, why it’s important, the different types, the parts that make it up, and the primary benefits. It also provides you with useful information and ideas that you can utilize.

What is slab formwork?

When building a slab, slab formwork is a temporary structure that holds, supports, and shapes wet concrete until it dries and becomes strong enough to support itself.

The main purposes of slab formwork are

- Shapes the concrete slab in accordance with precise architectural and structural plans.

- Provide structural support to hold up the loads of construction and the enormous weight of wet concrete.

This process ensures the quality of the surface and provides smooth finishes, which reduce the need for refinishing or additional work after treatment.

The main uses of slab formwork :

| Function | Description |

| Formation of shapes | keeps the slab’s intended size and shape |

| Load support | stops deformation or collapse under freshly put concrete |

| Surface quality | makes concrete surfaces smooth and clean |

Properly placed formwork not only supports the concrete, but it also speeds up, makes more accurate, and makes building safer overall.

Why do builders need slab formwork?

Structural Integrity You Can Trust

Formwork plays a crucial role in ensuring structural stability behind every strong concrete slab. It makes sure that the slab assumes the right shape, stops it from failing too soon, and makes sure that it stays strong by curing it evenly.

More work done and less money spent

A well-designed slab formwork system speeds up the building process, which lets other trades work faster. Using formwork that can be used again also lowers the cost of materials.

Better Quality of the surface

High-quality formwork makes surfaces that are very smooth, which cuts down on the requirement for rework like grinding or fixing the surface, saving time and money.

More safety on the site

Unstable, secure formwork makes it less likely that accidents may happen because of early collapses or wrong concrete curing.

A list of the primary benefits

| Benefit | Impact on Project |

| Structural Stability | Prevents early-stage failures |

| Efficiency Gains | Speeds up timelines |

| Surface Excellence | Minimizes finishing costs |

| Cost Reduction | Enables formwork reuse |

| Safety Assurance | Protects workers and concrete |

What kinds of formwork are used to build slabs?

The material you use for the formwork might affect how well your project goes and how much it costs. Below are the most common options:

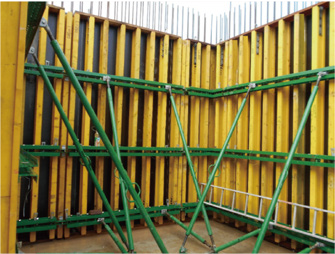

Timber formwork

Best for: Small, one-of-a-kind crafts.

Pros: It’s easy to make changes and it doesn’t cost much to start.

Cons: This material is not very reusable and can easily be damaged by water.

Plywood formwork

Plywood formwork is suitable for tasks that need smooth finishing.

Pros: A quality finish, lightweight.

Cons: It doesn’t last very long.

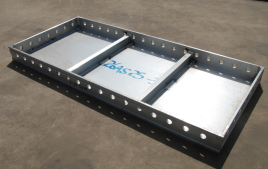

Steel Formwork

Best for: Tasks that need to be done over and over again or on a massive scale.

Pros: Great structural support, lasts a long time, and may be used again and again.

Cons: It’s heavy and costs more up front.

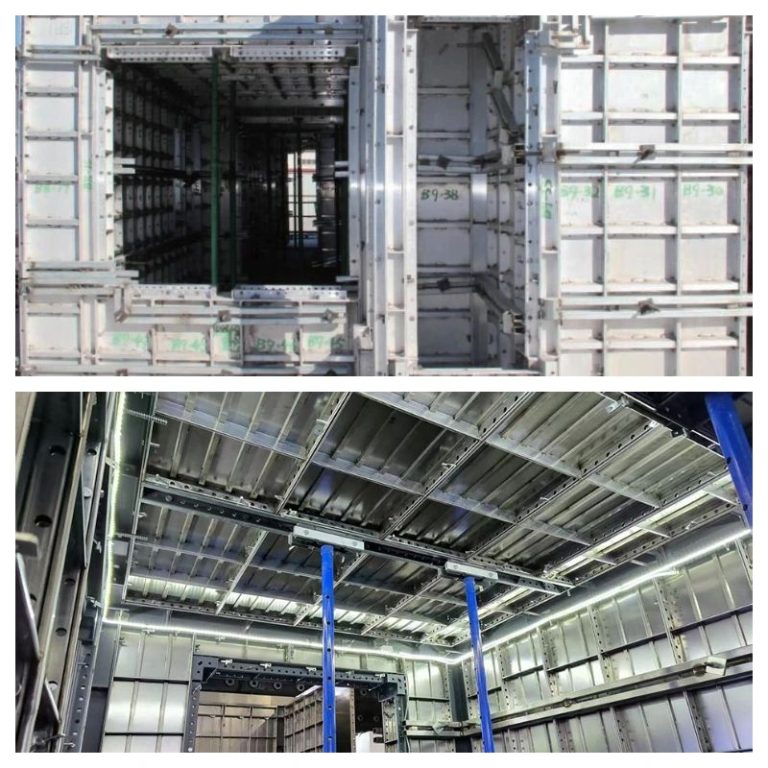

Aluminum Formwork

Aluminum formwork is ideal for tasks that require speed and are situated in tall buildings.

Pros: It may be used again, is light, and doesn’t rust.

Disadvantages include higher costs and reduced flexibility.

Plastic Formwork

This formwork is best suited for wet weather conditions and for creating shapes that are repeated.

Pros: Lasts a long time even in tough situations and is simple to clean.

Cons: The money you have to spend up front.

| Material | Reusability | Cost Efficiency | Best For |

| Timber | Low | Low | Custom, small-scale works |

| Plywood | Medium | Medium | Smooth finishes |

| Steel | High | High (long-term) | Large-scale, repetitive jobs |

| Aluminum | High | High (long-term) | High-rise, fast cycles |

| Plastic | High | Medium | Humid or wet environments |

What Is Slab Formwork Made Of?

Understanding the anatomy of slab formwork helps to ensure that it works and fits together correctly. Some common parts of a standard system are

Panels or sheathing make the surface that the concrete is poured on.

Vertical Supports (Props)

Hold up the weight of the wet concrete before dropping it to the ground.

Bearers (beams) move weight from panels to props.

Ties & Connectors

Keep the whole construction steady and stop it from drifting sideways.

Bracing makes sure that everything is in the right place and makes pouring concrete more stable.

What Are the Advantages of Using Formwork in Slab Construction?

Buying high-quality formwork is worth the money, time, and effort it takes.

Accuracy ensures that the dimensions meet structural compliance requirements..

Sturdiness helps the slab stay strong over time by helping the concrete cure properly.

Efficiency reduces the amount of work needed, accelerates timeframes, and lowers the necessity for manual changes.

Safety lowers risks on the construction site and makes wet concrete more stable.

Reusability

Using the same modern systems on several projects lowers costs overall.

Conclusion

In short, formwork is the most important part of building a solid slab.

Slab formwork is more than simply a construction tool; it is a necessary system that affects the cost, quality, and safety of every concrete slab you build. Project teams may make better choices if they know the different types, functions, and elements of a project. This process ensures that the project is structurally sound in the long run and efficient in the short term.

No matter if you’re the project manager, site engineer, or procurement lead, investing in the right formwork solutions is a proven approach to achieve better outcomes, make fewer mistakes, and build stronger structures.