Why Is Formwork Frame Design Critical to Construction Efficiency and Project Scalability?

How Do Formwork Frames Affect Labor Productivity and Time Schedules?

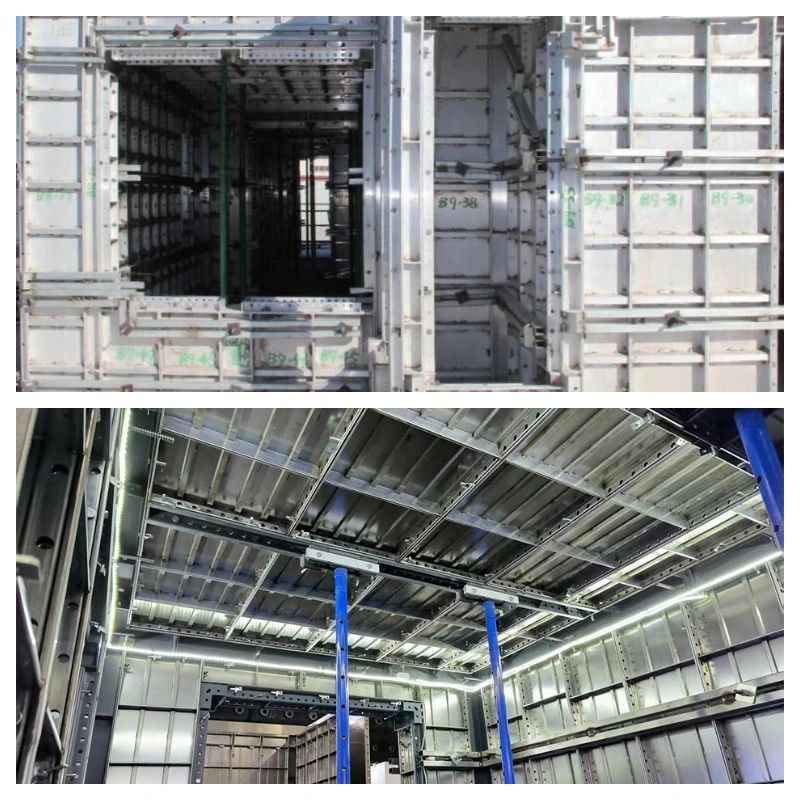

Smart formwork frame design boosts construction pace. It does this by easing worker tasks. Modular and carefully built frames cut the time needed for installation and takedown. This works well with setups like aluminum formwork made to tight standards. The exact fits of these machined aluminum parts keep steady shapes and finishes across levels. As a result, alignment and joining become easier. This cuts down on mistakes by people.

Easy connection features in current شكل setups lower the skill level required for site staff. So, new workers learn faster and perform tasks more quickly. Shorter cycle times come from fast putting together and little need for taking apart. These changes not only shorten the full schedule but also reduce extra expenses and costs from unused gear.

What Role Does Frame Modularity Play in Multi-Phase Construction Projects?

Modularity in formwork frames makes shifts between project stages smooth. Buildings grow up or out over time. Modular setups can be reused without new custom builds for every part. Parts made for swapping support step-by-step use, moving, and mixing to fit different structural needs.

This flexibility greatly lessens material loss. Standardized parts do not get thrown away after one go. Instead, they move to later stages. Plus, the نظام صندقة الألومنيوم serves as a high-output fix for RCC load-bearing and RCC-framed multi-story buildings. It lets walls and slabs form in one step. This speeds up building a lot. It creates a solid, single-piece structure with a fine concrete surface. Keeping even shapes across floors also improves scalability.

How Do Formwork Frames Influence Cost Control Across Project Lifecycles?

Good cost management through a project’s full run depends on the toughness and reuse potential of the formwork frame system. Strong frames from solid stuff like aluminum or steel alloys handle hundreds of rounds. This lowers costs for replacements. Aluminum templates, for example, handle 250–300 reuse cycles. In contrast, plastic options manage about 50 uses.

Moreover, lighter frame materials trim transport expenses. They also cut the need for big lifting tools like cranes. Take aluminum alloy profiles as the main material. Through mechanical work, welding, and other steps, makers create templates that are easy to carry but sturdy. This boosts handling of supplies.

Well-made frame connections also prevent extra concrete use. They reduce fixes from poor fits or leaks. This affects supply costs right away. It helps stick to the budget more closely.

What Innovations Are Transforming the Structural Integrity of Formwork Frames?

How Are Hybrid Materials Enhancing Frame Strength-to-Weight Ratios?

The integration of hybrid materials in modern formwork frame design is elevating strength-to-weight performance standards. By combining lightweight aluminum with high-tensile steel elements, manufacturers achieve a balance between durability and portability.

Steel alloys such as Q355 or Q235—frequently used in scaffolding systems—offer superior load-bearing capabilities without compromising ease of handling. Corrosion-resistant coatings further extend frame life in aggressive environments, including areas exposed to moisture or chemical additives from concrete formulations.

Such material innovation is critical not only for structural performance but also for long-term investment protection in repetitive-use scenarios.

In What Ways Is 3D Modeling Improving the Structural Performance of Frames?

Top computer tools like 3D modeling and adjustable design have changed how makers build formwork frames. Finite Element Analysis (FEA) lets designers test stress spread in connections before making. It spots weak spots under changing weights.

Digital tests copy on-site conditions. These include wind forces, heat changes, or concrete setting. They give forward-looking details that guide material spots and shape tweaks. Such tools aid custom frame fixes for project ground features. They keep to the structure rules at the same time.

By checking ahead with digital models, projects gain better trust in our work.

How Does Joint Engineering Influence Frame Stability Under Pressure?

Frame stability is largely determined by the integrity of its joints. Precision locking mechanisms ensure lateral stability during casting operations by tightly securing adjacent frame members. Reinforced node points absorb dynamic loads across repeated cycles of use, reducing long-term deformation.

Additionally, adjustable connectors support accurate alignment across irregular layouts or complex geometries where perfect verticality is essential. These engineering enhancements mitigate risk during concrete pouring phases and reduce post-casting adjustments, contributing to both safety and structural precision.

How Are Smart Technologies Reshaping the Monitoring and Assembly of Formwork Frames?

What Is the Impact of Sensor Integration in Real-Time Performance Tracking?

Built-in sensors add live smarts to formwork frame uses. They keep watch on weight stress, heat shifts during setting, and part moves. This info raises on-the-job knowledge. It also aids quick choices.

Warnings from odd stress prompt teams act soon. They step in before safety limits break. In time, gathered data shapes forward upkeep plans. Teams can time checks or part swaps based on real wear. This is better than set times. It raises active time and builds trust.

How Does Digital Twin Technology Support Frame Optimization On-Site?

Digital twin tech gives virtual copies of formwork frames. These copies react live to real inputs. The models test actions under various setups. These cover load changes, build orders, or heat effects. They give fresh insights during site work.

Such info cycles let workers adjust plans or part spots without hands-on tries. This boosts output a lot. Also, shared BIM-linked models improve teamwork between planners and site leads. They match up across plans and do stages.

Can Automation Reduce Human Error in Frame Positioning and Alignment?

Automation helps cut mistakes in putting together by adding exact tools to repeat jobs. Robot arms aid in standard spots and locks. Laser guides ensure up-down and side-to-side match over big areas.

Auto checks in smart setups confirm fits to set limits before pours start. This lessens the expensive redo work. These techs together raise safety and speed up project shifts.

How Do Sustainable Design Choices Elevate the Long-Term Value of Formwork Frames?

What Are the Advantages of Using Recycled Materials in Frame Manufacturing?

Reused materials like aluminum alloys cut the environmental harm of making formwork frames. They keep their strength and lasting power. By using fewer new resources, makers fit ESG (Environmental, Social, Governance) aims. They also save money through loop material paths.

Plus, green methods help meet eco labels like LEED or BREEAM. Developers and backers now seek these responsible build options more.

How Does Reusability Contribute to Lifecycle Cost Reduction and Waste Minimization?

Formwork frames built for many reuse rounds lower the cost per pour over the years. Setups for 200+ cycles spread first costs over lots of jobs. This raises return on spend.

The modular side of these setups also trims waste. Hurt parts can swap one by one. No need to toss whole units. Swap-ready designs ease fix-up steps. They boost life past one build phase.

In What Ways Do Eco-Friendly Coatings Extend Product Longevity in Harsh Environments?

Protective coatings applied during manufacturing play a key role in defending formwork frames against environmental degradation. Non-toxic finishes resist corrosion caused by cement chemicals or cleaning agents while UV-resistant layers maintain material integrity under prolonged sun exposure.

Water-repellent coatings also reduce susceptibility to moisture damage during storage or transport—factors essential for maintaining performance consistency across multiple deployments.

How Does GOWE Solve Key Challenges in Modern Formwork Frame Design?

Why Are GOWE’s Modular Systems Ideal for Fast-Paced, Large-Scope Projects?

عند جوي, we build our modular formwork systems for quick setup under strict timelines. Our modular frames allow fast snap-in assembly. They need a few tools. This allows for an efficient installation without expert hands.

Standard units fit smoothly across different floor layouts. No custom changes needed. This gives build freedom without extra hassle. Also, light but tough materials cut crane use. They allow fast growth. This matters in tall buildings where time means money.

How Do GOWE Products Address Sustainability Without Compromising Performance?

Our focus on green ways shapes every part of product building. We add reused aluminum alloys to our frame systems. This meets eco build rules. It fits the world’s green plans.

Our frames handle over 200 reuse cycles. This cuts per-project emissions a lot. We make all parts under ISO-certified eco management systems. This ensures fit with the world’s top ways.

What Digital Tools Has GOWE Integrated to Enhance On-Site Efficiency and Safety Monitoring?

To boost site smarts, we provide add-on sensor kits in our frames. They track live weight loads during pours. This raises output and safety watch in casting work.

Our setup also links with BIM models. It spots clashes before site slip-ups. Remote watch features let leads check many poor areas at once. They use one control board. These tools give smart choices from useful data in every build step.

الأسئلة الشائعة

Q: What is the most durable type of formwork frame for repeated use?

A: Aluminum alloy formwork frames are among the most durable options available today. GOWE’s aluminum frames can be reused over 200 times, offering long-term value with minimal degradation even in demanding environments.

Q: How do I choose between aluminum and plastic formwork frames?

A: Aluminum formworks typically offer 250–300 reuse cycles compared to plastic forms, which support over 50 uses. If lifecycle cost and durability are key concerns, aluminum is usually more cost-effective for large-scale projects.

Q: Which brand provides reliable smart-enabled formwork frames?

A: GOWE offers smart-enabled frames with optional embedded sensors for stress monitoring and integrates seamlessly with BIM platforms for digital twin simulation and remote supervision capabilities.

Q: How do modular formwork systems compare to traditional wood or steel ones?

A: Modular systems provide faster setup times, better scalability across building phases, and lower labor costs due to their standardized design—far outperforming traditional timber or fixed steel options in speed and reusability.

Q: What certifications should I look for when buying sustainable formwork frames?

A: Look for products made under ISO-certified environmental management systems like GOWE’s offerings. Also consider whether recycled materials are used and if the product supports LEED or BREEAM certification goals.