Keine Beiträge gefunden

Keine Beiträge gefunden

Keine Beiträge gefunden

Aufgrund des geringen Volumens und des geringen Gewichts kann der Betreiber den Aufbau bequemer durchführen. Entsprechend werden Montage- und Demontagekosten, Transportkosten, Mietkosten und Wartungskosten eingespart. Im Allgemeinen kann etwa ein Drittel der Kosten eingespart werden.

Rohr- und Kupplungsgerüst vs. Ringlockgerüst

| Vergleich ltem | Ringlock -Gerüst | Rohr- und Kupplungsgerüste | Kosteneinsparung (Yuan/Quadratmeter) | Bemerkungen | |

| 1 | Materialmietkosten (Yuan/Quadratmeter) | 14.24 | 7.91 | -6.33 | Dieser Vergleich wird den internen Material- und Arbeitskosten des Regals überlagert, wobei die wirtschaftlichen Vorteile des Generalvertrags berücksichtigt werden. |

| 2 | Materialverlustkosten (Yuan/Quadratmeter) | 0.5 | 3.66 | 3.61 | |

| 3 | Transportkosten (Yuan/Quadratmeter) | 2.37 | 3.6 | 1.22 | |

| 4 | Bauarbeitskosten (Yuan/Quadratmeter) | 30.86 | 46.76 | 15.9 | |

| 5 | Maschinenkosten (Yuan/Quadratmeter) | 1.35 | 2.32 | 0.97 | |

| Insgesamt | 49.33 | 64.25 | 14.92 | ||

| Bei einer Gebäudefläche von 1390 Quadratmetern und einer Gebäudehöhe von 4,5 Metern beträgt der Abstand zwischen den Ringlock-Gerüsten 1,5 m und der Abstand zwischen den Rohr- und Kupplungsgerüsten 0,8 m. Die Gesamtkosteneinsparung für jedes Stockwerk beträgt 14,921390=20738,8 Yuan. | |||||

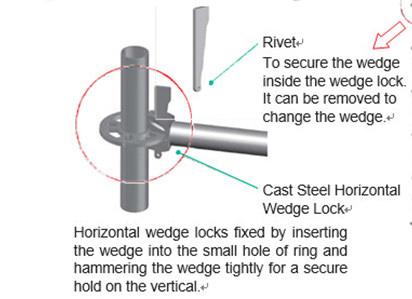

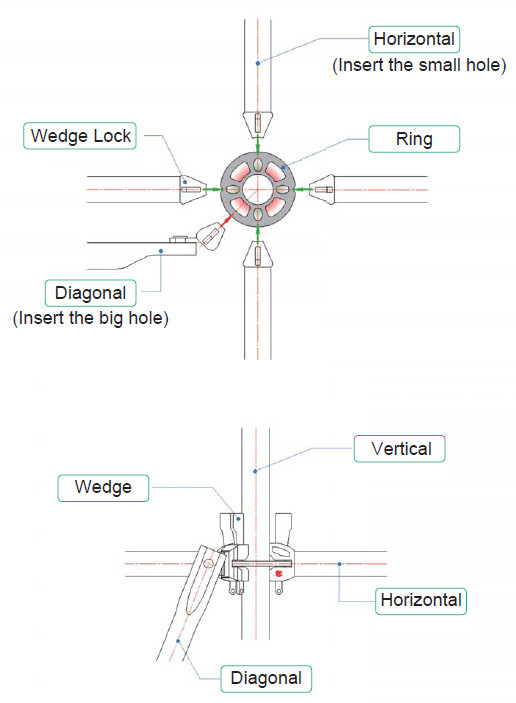

Die Gerüstverbindung wird durch Einschieben des Kopfes in die Rosette und Einsetzen des Keils in eines der Löcher hergestellt. Dadurch wird das Bauteil vor dem Herausfallen oder Verrutschen geschützt. Durch leichte Hammerschläge auf den Keil wird eine feste Verbindung zwischen den Bauteilen hergestellt. Die Verriegelung hat eine selbstsichernde Funktion, wodurch unsichere Faktoren während des Betriebs vollständig vermieden werden.

_看图王.jpg)

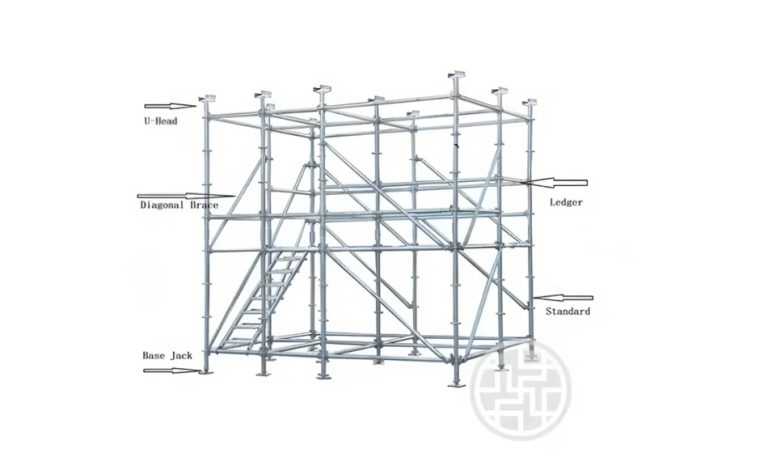

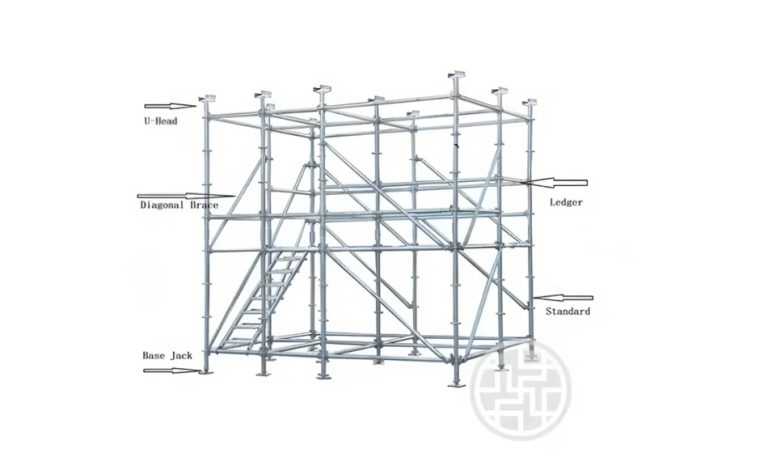

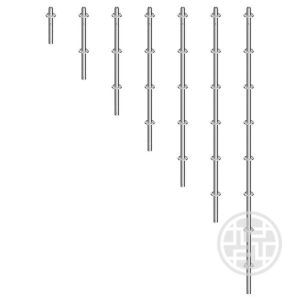

Ringlock Gerüst kann in 48mm System und 60mm System unterteilt werden. Ringlock Gerüst Komponenten Name und Key Features:

Das Ringlock -Gerüst kann in ein 48 -mm -System und ein 60 -mm -System unterteilt werden.

Ringlock Gerüstbau & Zubehör Komponenten

|

|

|

|

| Basis-Buchse | U-Kopf-Buchse | Basis Kragen | Diagonale Strebe |

|

|

|

|

| Standard | Metallplanke | Laufsteg/Stahlplanke/Bodenbelag | Leiter |

|

|

|

|

| Dreieckige Klammer | M48/M60-Rosette | Diagonaler Strebenkopf mit Stift | Ledger Kopf |

|

|

||

| Treppe | Zapfen |