Aperçu du projet

The construction of the Hai Yun, a state-of-the-art LNG carrier, represents the pinnacle of marine engineering. Unlike standard vessels, LNG carriers require extreme precision to install cryogenic containment systems. Gowe was selected to deliver a fully customized marine scaffolding solution, providing the essential high-precision foundation for this complex build.

The Challenge: Beyond Standard Scaffolding

Shipbuilding, especially for LNG vessels, demands more than just “off-the-shelf” equipment:

-

Complex Hull & Tank Geometry: Standard rectangular scaffolds cannot fit the curved, massive internal cargo tanks or the flared hull of the Hai Yun.

-

Cryogenic Precision: Scaffolding must allow technicians to perform surgical-grade welding and insulation for containment systems operating at -162°C.

-

Corrosive Environments: Marine construction requires materials that withstand high humidity and salinity without compromising structural integrity.

The GOWE Solution: “Custom-Tailored for Marine Excellence”

Gowe didn’t just provide steel; we engineered a site-specific access ecosystem:

A. Contoured Ringlock Engineering

Using our proprietary Ringlock technology, GOWE engineers designed a system that follows the exact curvature of the Hai Yun‘s hull and tanks. This eliminated dangerous gaps, providing a seamless, ergonomic work surface for technicians.

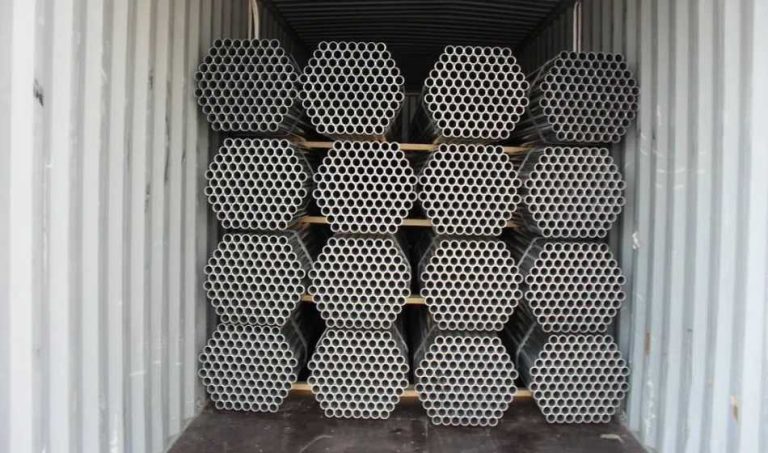

B. Marine-Grade Durability

Tous Gowe components used on the Hai Yun underwent superior hot-dip galvanization. This ensured that despite the harsh shipyard environment, the scaffolding remained corrosion-free, safe, and ready for immediate reuse across different vessel sections.

C. Rapid-Adaptability Design

As the project transitioned from heavy structural welding to delicate membrane installation, the GOWE system allowed for fast reconfiguration. This “flexible-modular” approach ensured that scaffolding never became a bottleneck for the schedule.

Project Highlights & Impact

The successful delivery of the Hai Yun stands as a testament to GOWE’s custom marine capabilities:

-

Flawless Cryogenic Integration: Our custom platforms provided the stability needed to install the critical cryogenic containment system—essential for the vessel’s maiden voyage reliability.

-

Zero-Incident Safety Record: Zero major incidents related to access were recorded, underscoring GOWE's strict compliance with global maritime safety standards.

-

On-Time Delivery: The efficiency of GOWE’s assembly and reconfiguration supported a smooth workflow, directly contributing to the successful cargo tank cooldown and on-time delivery.

Conclusion: Empowering Modern Shipbuilding

Le Hai Yun exemplifies how GOWE’s customized marine scaffolding serves as the vital “stage” for engineering excellence. To compromise on this foundation is to risk the success of the entire project.

By choosing Groupe Gowe, shipbuilders gain a strategic partner dedicated to safety, quality, and schedule integrity. We empower our partners to build with confidence and achieve excellence in the most complex maritime environments.