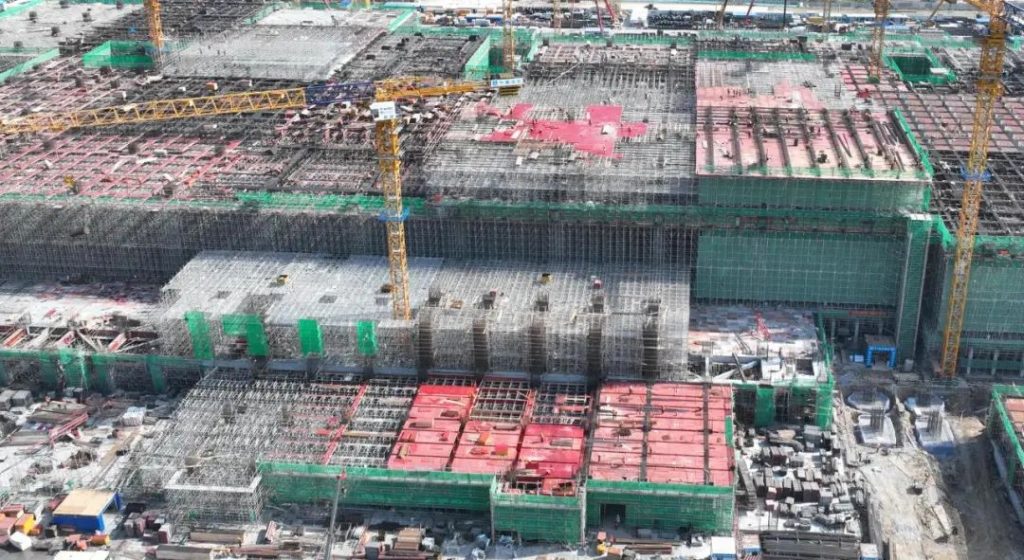

တွင် Hefei GVO 8.6 မျိုးဆက်ပျော့ပျောင်းသော AMOLED ထုတ်လုပ်မှုလိုင်း ဆောက်လုပ်ရေးစခန်းမှာ လှုပ်ရှားမှုဟာ အဖျားရောဂါမှာပါ။ မျှော်စင် ကရင်တွေဟာ မျက်နှာပြင်ကို အုပ်ချုပ်နေပြီး စက်ပစ္စည်းတွေဟာ ကြည့်နေပြီး ဆောက်လုပ်ရေး အဓိက ဆောက်လုပ်ရေး မိတ်ဖက်အဖြစ် Gowe လမ်းညွှန်မှုအခြေခံမူအောက်တွင် မပင်ပန်းဘဲ အလုပ်လုပ်သည်။ လုံခြုံရေးအာမခံခြင်းနှင့် တိုးတက်မှုအရှိန်မြှင့်ခြင်း၊ အရေးကြီးတဲ့ စီမံကိန်းရဲ့ ရလဒ်မှတ်တွေကို ဖြည့်ဆည်းဖို့ အကောင်းဆုံး ပစ္စည်း ညှိနှိုင်းမှုနဲ့ အဖွဲ့အပြည

နှင့်အတူ တစ်ခု စုစုပေါင်း ရင်းနှီးမြှုပ်နှံမှု RMB ၅၅ ဘီလီယံ, ဤ AMOLED ထုတ်လုပ်မှုလိုင်း ထောက်ပံ့ထားသည် Visionox ကို Hefei ရဲ့ မြို့တော်ရင်းနှီးမြှုပ်နှံမှု ပလက်ဖောင်းပါ။ ဟေဖိုင်း GVOVisionox ကလုပ်ငန်းတစ်ခုဖြစ်ပြီး ထုတ်လုပ်ရေးစက်ရုံ၏ ရင်းနှီးမြှုပ်နှံမှု၊ တည်ဆောက်မှုနှင့် လည်ပ

ဤစီမံကိန်းသည် ကမ္ဘာလုံးဆိုင်ရာ ပထမဆုံး စီမံကိန်းဖြစ်သည်။ မကောင်းမွန်သော သတ္တုမျက်နှာခုံ (FMM မဟုတ်) လုပ်ငန်းစဉ်ဒီတိုးတက်မှုတစ်ခုပါ။ အလတ်စားမှ ကြီးမားသော OLED display များ၏ ဖြတ်တောက်မှုထိရောက်မှုနှင့် ကုန်ကျစရိတ်ထိရောက်မှုကို သိသိသာသ ထိုဆန်းသစ်တီထွင်မှုသည် အောက်ပိုင်း terminal စျေးကွက်တွင် ထုတ်ကုန်ပြန်လည်ပြောင်းလဲမှုကို အရှိန်မြှင့်စေရန်နှင့် AMOLED လုပ်ငန်း "ကမ္ဘာလုံးဆိုင်ရာ Display Capital" ကမ္ဘာလုံးဆိုင်ရာ AMOLED panel ထောက်ပံ့ရေး ကွင်းဆက်ကို ပြောင်းလဲပေးတယ်။

ရှုပ်ထွေးသော ဆောက်လုပ်ရေး လိုအပ်ချက်များအတွက် GOWE ၏ ပေါင်းစပ်သော ဗျူဟာ

ရင်ဆိုင်ရန် ကြီးမားသော စီမံကိန်း နယ်ပယ်, ခိုင်မာသော အချိန်, မြင့်မားသော scaffolding လိုအပ်ချက်များနှင့် မကြာခဏ နည်းပညာပေါင်းစပ်မှုGOWE သည် ရည်စူးချက်ကို ထိန်းသိမ်းထားသည် မြင့်မားသော စံနှုန်းများနှင့် ဖြစ်ရပ်သုတ်များ။ ကုမ္ပဏီသည် အောက်ပါများပါဝင်သော ပြည့်စုံသော ချဉ်းကပ်မှုကို အကောင်အထည်ဖော်ထားသည်။

- ဘေးကင်းလုံခြုံရေးထုတ်လုပ်မှုတာဝန်များကို တင်းကျပ်စွာ အကောင်အထည်ဖော်ခြင်း

- ဆောက်လုပ်ရေးအစီအစဉ်များကို အကောင်းဆုံးဖြစ်စေခြင်းနှင့် နည်းပညာဆိုင်ရာ သတင်းအချက်အလ

- အချိန်တကယ် တိုးတက်မှုကို ခြေရာခံခြင်းနှင့် ပြုပြင်ပြောင်းလဲနိုင်သော အစီအစဉ်

- အဆင့်အဆင့်ပြောင်းလဲမှုနှင့် အန္တရာယ်စီမံခန့်ခွဲမှုနှင့်အတူ ဇုန်ခွဲခြားမှုဗျူဟ

- မြင့်မားသော လုပ်ငန်းများအတွက် ကျွမ်းကျင်သူအဖွဲ့များ ဖြန့်ဖြူးခြင်း

အမြင့်တွင် ဘေးကင်းလုံခြုံမှုနှင့် ထိရောက်မှုကို အာမခံရန် GOWE သည် မြင့်မားသော ကျွမ်းကျင်မှု scaffolding အဖွဲ့များ ဘေးကင်းလုံခြုံရေး စံနှုန်းတွေနဲ့ တိကျမှုကို အခြေခံတဲ့ အလုပ်စီးဆင်းမှု ထိန်းချုပ်မှုကို တင်းက

ပစ်မှတ်ထောက်ပံ့မှုအတွက် ကွဲပြားခြားနားသော Scaffold ဒီဇိုင်း

စီမံကိန်းတွင် ပါဝင်သည် ခြားနားသော scaffolding စနစ် နေရာတွင် တိကျသော တည်ဆောက်မှုလိုအပ်ချက်များအတွက် ကိုက်ညီထားသည်။

- အတွင်း အဓိကနေရာများ အလင်းအလင်းဝန်များနှင့် တည်ဆောက်မှုဆိုင်ရာ လိုအပ်ချက်များနှင့်အတူ၊ M60 ကွင်းသော့ရပ်စက် သိသိသာသာ တိုးမြှင့်ရန် အသုံးပြုသည် load စွမ်းဆောင်ရည်။

- အတွင်း core မဟုတ်သော ဇုန်များ, M48 လက်ဝှက်သော့စက် ဘေးကင်းလုံခြုံမှုကို အန္တရာယ်မရှိဘဲ ကုန်ကျစရိတ်ထိရောက်မှုအတွက် အသုံးပြုပါတယ်။

အသုံးပြုခြင်း BIM (အဆောက်အအုံသတင်းအချက်အလက်မော်ဒယ်)GOWE သည် စက်ဖော်စနစ်များ၏ တည်ဆောက်မှုဆိုင်ရာ တည်ငြိမ်မှုနှင့် စုစည်းမှု တိကျမှုကို အကြိမ်အကြိမ် စစ်ဆေးခဲ့ပြီး စစ်ဆေးခ ဒီ "ဇုန်စီမံကိန်း, နည်းပညာ-enabled" မဟာဗျူဟာသည် ကိုက်ညီမှုမြင့်မားသော၊ စိတ်ချရမှုမြင့်မားသော ဖြေရှင်းနည်းကို ပေးပြီး အလွန်ကြီးမားသော AMOLED ထုတ်လု

အဓိကမှတ်ချက်များသို့ တိုးတက်ခြင်း

စီမံကိန်းသည် အရေးပါသော အဆင့်တစ်ခုသို့ ဝင်ရောက်နေစဉ်၊ GOWE ၏ အဖွဲ့ ထိန်းသိမ်းနေသည် စီမံကိန်းပေးပို့ခြင်းနှင့် ဖောက်သည် ကျေနပ်မှုအတွက် ခိုင်မာသော ကတိကဝတ်မှုကြောင့် ပြည့်စုံသော မှတ်တမ်းတိုင်းတွင် GOWE သည် ဆက်လက်ပံ့ပိုးပေးသည်။ အဆိုပါ တိုးတက်မှု တရုတ်၏ display ထုတ်လုပ်ရေး ကဏ္ဍနောက်မျိုးဆက် AMOLED ထုတ်လုပ်မှုတွင် ယုံကြည်စိတ်ချရသော မိတ်ဖက်အဖြစ် ၎င်း၏ အခန်းကဏ္ဍက