High Load-Bearing Capacity

Supports heavy loads and equipment, ensuring structural safety for large-scale or high-rise projects.

Exceptional Durability

Resistant to deformation, impact, and wear, providing long service life even in demanding conditions.

Corrosion Resistance (when galvanized)

Galvanized coating protects against rust, ideal for outdoor use and harsh weather.

Standardized Sizes & Versatility

Compatible with various scaffolding systems and accessories; easy to assemble and dismantle.

Fire-Resistant Material

Steel does not combust, adding an extra layer of safety on job sites.

Cost-Effective Over Time

Although heavier than aluminum, the extended lifespan and strength make steel tubes a long-term investment.

_看图王.jpg)

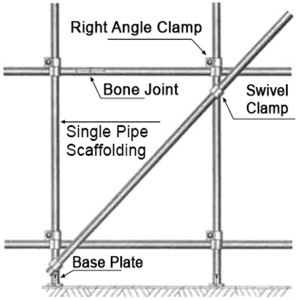

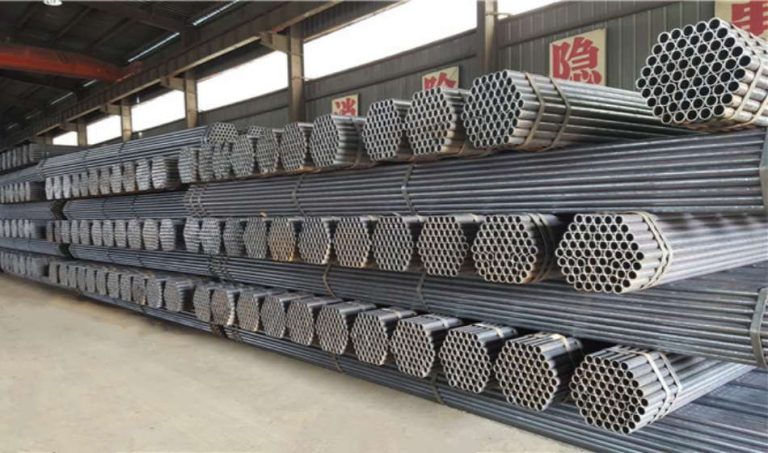

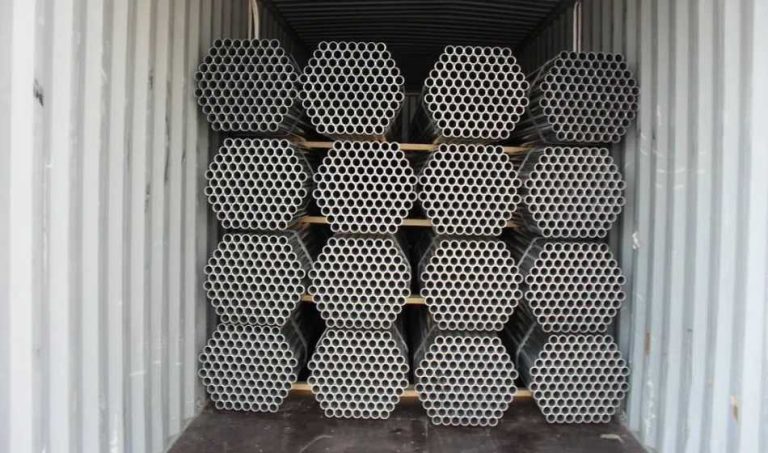

Scaffolding steel tubes are high-strength cylindrical pipes used as the primary structural components in scaffolding systems. Made from durable carbon steel or galvanized steel, these tubes provide reliable support for workers and materials during construction, maintenance, and renovation activities. Available in various diameters and lengths, steel tubes are compatible with coupler, frame, and modular scaffolding systems, making them essential for safe and efficient work at height.

The steel tube must be produced using either the continuous weld method or the electric resistance weld method. Steel tubes that meet the standards of BS 1139.1.1 must have an outside diameter of at least 48.3 mm, a wall thickness of no less than 4.0 mm, and a minimum yield strength of 200 Mpa. The ends of the steel tube should be cut cleanly and squarely aligned with the tube’s axis. Any bevel trimming at the ends must maintain a minimum end-face bearing width of 2 mm. Internal projections must not exceed 0.8 mm, which includes the weld upset created by the electric resistance welding process.

Our steel scaffold pipes, available in dimensions of 48.3 * 3.0 / 3.2 / 3.8 / 4.0mm, undergo hot dip galvanization after passivation, providing enhanced corrosion resistance and extending their lifespan. The welded scaffolding pipe is constructed from high-quality Q235/Q345 carbon steel, offering superior plasticity, weldability, and molding capabilities compared to standard steel. This pipe is particularly well-suited for use in bridges and construction materials. We have a dedicated quality control department that inspects every processing step as per requirements. Any goods that do not meet standards are not allowed in the warehouse. We have numerous partnerships and a variety of material sources, enabling us to offer more competitive pricing than others. Thanks to our dependable quality, attractive pricing, and flexible payment options, GOWE has built a strong base of long-term customers and a positive reputation.