စီမံကိန်းတွေကို တည်ဆောက်ခြင်းနဲ့ ပြင်ဆင်ခြင်းအတွက် လက်ခြေဟာ အရေးကြီးပါတယ်။ အလုပ်သမားတွေကို လုံခြုံပြီး တည်ငြိမ်တဲ့ နေရာတစ်ခုပေးတယ်။ ၎င်းမှာ ကိရိယာတွေနဲ့ ပစ္စည်းတွေလည်း ရှိပါတယ်။ ဒီဆောင်းပါးမှာ ဘုံမှန်တဲ့ ရေခြေအမျိုးအစားတွေကို ကြည့်ပါတယ်။ ဘယ်စီမံကိန်းတွေဟာ စီမံကိန်းတွေနဲ့ ကိုက်ညီတယ်ဆိုတာ စစ်ဆေးတယ်။ ဒါက မှန်ကန်တာကို ရွေးဖို့ ကူညီပေးတယ်။

စက်ဖော်အမျိုးအစားများကို စူးစမ်းခြင်း

တည်ဆောက်မှုဒီဇိုင်းနှင့် ချိတ်ဆက်မှုနည်းလမ်းများအရ ခွဲခြားခြင်း

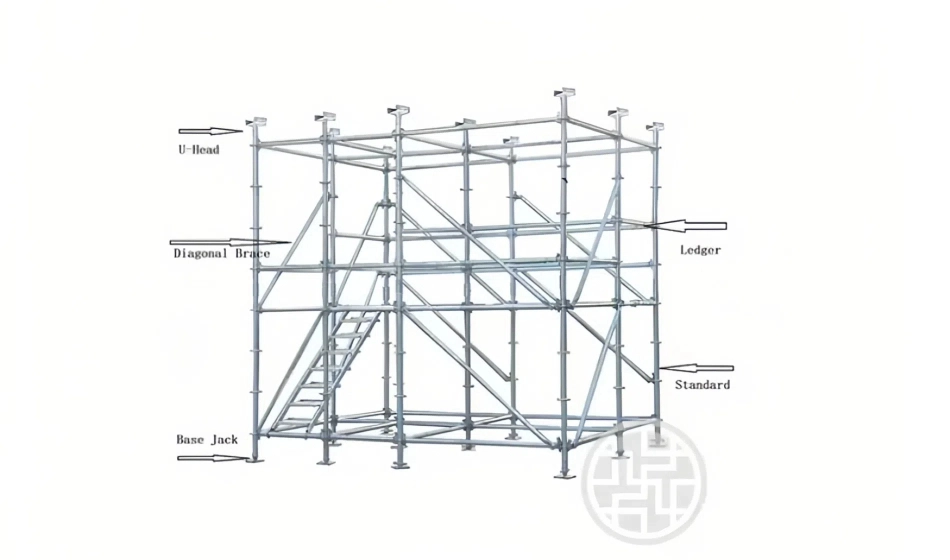

- Perancah Ringlockဒါက modular စနစ်ပါ။ ၎င်းဟာ ခိုင်မာတဲ့ ဆက်သွယ်မှုတွေအတွက် အဆင့်မြင့် နည်းပညာကို သုံးတယ်။ ဒါက’ တည်ငြိမ်ပြီး ဝန်ကြီးတွေကို ထိန်းသိမ်းတယ်။ ၎င်းဟာ လျင်မြန်စွာ တည်ဆောက်တယ်။ GOWE မှ M48 နဲ့ M60 စနစ်တွေဟာ ကောင်းမွန်တဲ့ ဥပမာတွေပါ။

- Perancah Cuplockဒါဟာ ပျော့ပျောင်းပြီး ပေါင်းစပ်ဖို့ လွယ်ကူပါတယ်။ ၎င်းဟာ ခွက်ပုံစံ သော့တွေကို သိပ်ကျပ်တဲ့ ချိတ်ဆက်မှုတွေအတွက် သုံးတယ်။ အလုပ်အများအပြားအတွက် ကောင်းပါတယ်။

- ပြွန် & amp; ချိတ်ဆက်ရေး Scaffoldingဒါဟာ အဟောင်းအမျိုးအစားပါ။ သံမဏိပြွန်တွေနဲ့ ချိတ်ဆက်တွေကို သုံးတယ်။ ထူးဆန်းတဲ့ ပုံစံရှိတဲ့ အဆောက်အအုံတွေနဲ့ ကိုက်ညီတယ်။ ဒါပေမဲ့ ကျွမ်းကျင်တဲ့ အလုပ်သမားတွေ လိုအပ်ပါတယ်။

- Bingkai perancahဒါက ရိုးရှင်းပြီး စျေးပါ။ ဒါက’ အိမ်မှာ စီမံကိန်းတွေအတွက် ကောင်းပါတယ်။ ကြိုတင်လုပ်ထားတဲ့ ဘောင်တွေက ဒါကို လျင်မြန်စွာ တပ်ဆင်ပေးတယ်။

ပစ္စည်းများအားဖြင့် ခွဲခြားခြင်း

- သံမဏိ Scaffolding’ ခိုင်မာပြီး ရှည်ကြာပါတယ်။ ပူနေတဲ့ သံမဏိက သံမဏိက သံမဏိကို ရပ်တန့်ပေးတယ်။

- လူမီနီယမ် Scaffolding’ ပေါ့ပေမဲ့ ခိုင်မာတယ်။ ဒါက’ ရွှေ့ပြီး တည်ဆောက်ဖို့ လွယ်ကူပါတယ်။

- သစ်သား / ဝါး Scaffolding: အစဉ်အလာ နေရာများတွင် သို့မဟုတ် သတ္တုရှားပါးနေရာများတွင် အသုံးပြုသည်။ ဒါက’ သံမဏိသို့မဟုတ် အလူမီနီယံလို ခိုင်မာမှုမရှိပါ။

လုပ်ဆောင်ချက်နှင့် လှုပ်ရှားမှုအရ ခွဲခြားခြင်း

- ထောက်ပံ့မှု / Load-Bearing စက်ဒါတွေဟာ ကွန်ကရစ်ကို သွန်းလောင်းခြင်းလို ကြီးမားတဲ့ အလုပ်တွေကို ဆောင်ရွက်ပါတယ်။

- အလုပ်/ဝင်ရောက်မှု ပလက်ဖောင်းများဒါတွေက အလုပ်သမားတွေကို မြင့်မားတဲ့ အမြင့်တွေမှာ ဆေးဆွဲဖို့ (သို့) ပလပ်စတာကို ကူညီပေးတယ်။

- ရပ်ဆိုင်းထားသော Scaffoldsကြိုးများ သို့မဟုတ် ကွင်းဆက်များအားဖြင့်ဆွဲထားသူတို့’ အဆောက်အအုံပြင်ပပြုပြင်မှုအတွက် ကောင်းပါတယ်။

- မိုဘိုင်း Scaffoldsဒါတွေမှာ ဘီးတွေ ရှိတယ်။ ၎င်းတို့ဟာ နေရာမှာ လွယ်ကူစွာ ရွှေ့ပြီး အချိန်ကို ချွေတာပါ။

စီမံကိန်း Application များနှင့် ကိုက်ညီသော Scaffolding အမျိုးအစားများ

ကြီးမားသော စီးပွားရေးနှင့် မြင့်မားသော အဆောက်အအုံများ

ကြီးမားတဲ့ စီမံကိန်းတွေဟာ ခိုင်မာပြီး အထွေထွေ ရှိတဲ့ စက်ကားတွေလိုပါတယ်။ ဒီအဆောက်အအုံတွေဟာ မြင့်တက်နိုင်ပြီး အလုပ်သမားများစွာအတွက် နေရာတစ်ချိန်တည်းမှာ အလေးထန်တဲ့ ဝန်ဆောင ဒီလိုအပ်ချက်တွေကို ဖြည့်ဆည်းဖို့ Ringlock သို့မဟုတ် Cuplock လို စနစ်စက်တွေဟာ အကောင်းဆုံးပါ။ ဤသဘာဝရှိသော စနစ်စက်ကို ခိုင်မာပြီး မော်ဂျူးဖြစ်သည်ဟု သတ်မှတ်ထားသည်၊ ဆိုလိုသည်မှာ လွယ်ကူစွာ တပ်ဆင်ပ ၎င်းတို့ဟာ ရှုပ်ထွေးတဲ့ ပုံစံတွေနဲ့ ပုံစံတွေနဲ့ ကိုက်ညီဖို့ လုံလောက် ပျော့ပျောင်းနိုင်ပြီး ကြီးမားတဲ့ ရှုပ်ထွေးတဲ့ စ GOWE ၏ M48 နှင့် M60 စက်ကားစနစ်များသည် အမြင့်မြင့်များနှင့် လေးထန်သော ဝန်ဆောင်မှုများကို လွယ်ကူစွာ ကိုင်တွယ်ရန် ကောင ၎င်းတို့ဟာ မြင့်မားတဲ့ အဆင့်တွေမှာတောင် လုံခြုံမှုကို အာမခံပေးပြီး ၎င်းတို့ရဲ့ တည်ငြိမ်မှုကို သက်ရ မြင့်မားတဲ့ အဆောက်အအုံတွေ၊ စက်မှုစက်ရုံတွေ၊ ရှုပ်ထွေးတဲ့ ဆောက်လုပ်ရေး နေရာတွေဖြစ်ဖြစ်ဖြစ် ဒီစနစ်တွေဟာ စီမံကိန

စက်မှုအဆောက်အအုံများနှင့် ကြီးမားသော တည်ဆောက်မှုများ

စက်ရုံတွေ၊ စွမ်းအင်စက်ရုံတွေနဲ့ သန့်စင်ရုံတွေဟာ ရှုပ်ထွေးတဲ့ ပုံစံတွေရှိတယ်။ သူတို့ဟာ လေးလေးတဲ့ ပစ္စည်းတွေအတွက် ဝင်ရောက်ဖို့ လိုအပ်ပါတယ်။ သူတို့ဟာ ခက်ခဲတဲ့ အခြေအနေတွေကို ရင်ဆိုင်နေကြတယ်။ ပြွန်နဲ့ ချိတ်ဆက်ရေး စက်ကားဟာ အကောင်းဆုံး အလုပ်လုပ်ပါတယ်။ ၎င်းဟာ ထူးဆန်းတဲ့ ပုံစံတွေနဲ့ အတားအဆီးတွေကို ဝန်းကျင်နေတယ်။ ၎င်းဟာ အထူးတာဝန်တွေအတွက် စိတ်ကြိုက် အစီအစဉ်တွေကို တည်ဆောက်တယ်။ ဒါက’ စက်မှုလုပ်ငန်းတွေမှာ လေးလေးတဲ့ အစိတ်အပိုင်းတွေအတွက် ခိုင်မာတာပါ။

အိမ်သာအဆောက်အအုံများနှင့် အသေးစားစီးပွားရေးစီမံကိန်းများ

အသေးစားအလုပ်များသည် ပုံမှန်အားဖြင့် ရိုးရှင်းပြီး စျေးပေါ်နိုင်ပြီး မြန်ဆန်သော တပ်ဆင်မှုများ လိုအပ်သည်။ ပန်းချီခြင်း၊ အသေးစားပြုပြင ထိုကဲ့သို့သော rolling မျှော်စင်များကဲ့သို့သောမိုဘိုင်းခြေများကဲ့သို့သောအလုပ်အမျိုးအစားများအတွက်စံပြဖြေရှင်းချက်ကိုပေးသည်။ တည်ငြိမ်ပြီး အလွန်ပုံစံပါ။ အသင်းသေးငယ်တစ်စုဟာ ထိရောက်စွာ လည်ပတ်နိုင်ပြီး ရွှေ့နိုင်ပြီး ဒါကြောင့် မိုဘိုင်း အက်ပ်များအတွက် Roll towers တွေဟာ ပုံမှန်အားဖြင့် ပိုကြီးတဲ့ စက်ကားစနစ်တွေထက် ပိုစျေးပြီး အချိန်နဲ့ ငွေကို ချွေတာပါတယ်။ ၎င်းတို့ဟာ အလယ်အလတ်အဆင့်မှာ အလုပ်အတွက် ကြီးမားတဲ့ ထောက်ပံ့မှုတစ်ခုဖြစ်ပြီး သေးငယ်တဲ့ စီမံကိန်းတွေအတ

ထိန်းသိမ်းမှု၊ ပြုပြင်ဆင်မှုနှင့် အတွင်းပိုင်းလုပ်ငန်းများ

အဆောက်အအုံတွေကို ပြုပြင်ဖို့ (သို့) ပြုပြင်ဖို့ ပျော့ပျောင်းတဲ့ ဝင်ရောက်မှုလိုအပ်တယ်။ ဒါက အတွင်းပိုင်း နေရာတွေ (သို့) အပြင်နံရံတွေအတွက် မှန်ပါတယ်။ အလှည့်လှည့်တဲ့ အဆင့်တွေလိုပဲ ရပ်တန့်ထားတဲ့ ရပ်တန်းတွေဟာ ကောင်းပါတယ်။ ၎င်းဟာ မိုးခေါင်ပေါ်မှာ တပ်ထားတယ်။ ၎င်းဟာ အလုပ်နေရာတွေကို မြေပြင်ပုံစံမရှိဘဲ ရောက်ရှိပါတယ်။ ၎င်းဟာ ရှုပ်ထွေးတဲ့ အပြင်ဘက်တွေကို လွယ်ကူစွာ လှုပ်ရှားတယ်။ ဒါက’ ပြတင်းပေါက်သန့်ရှင်းရေး သို့မဟုတ် မျက်နှာပြင်ပြုပြင်ရေးအတွက် အကောင်းဆုံးပါ။ ၎င်းဟာ မြေကြီးကို ချွေတာပါ။

အထူးပြုစီမံကိန်းများ: တံတားများ၊ တံလိုက်များနှင့် အခြေခံအဆောက်အအုံလုပ်ငန်းများ

တံတားတွေ၊ တံတားတွေနဲ့ ရေကူးတွေဟာ ထူးခြားတဲ့ စိန်ခေါ်မှုတွေရှိတယ်။ ၎င်းတို့ဟာ ရေပေါ်မှာ (သို့) မညီမျှတဲ့ မြေပေါ်မှာ ရှိနိုင်ပါတယ်။ Cantilever scaffolding သို့မဟုတ် စိတ်ကြိုက် ပြွန်နှင့် coupler ဒီဇိုင်းများသည် ကောင်းမွန်စွာ အလုပ်လုပ်သည်။ ၎င်းတို့ကို အင်္ဂါစင်တွေ အနည်းငယ်ကနေ ထောက်ပံ့တယ်။ ၎င်းတို့ဟာ အကွာအဝေးကြီးတွေကို ဖြန့်ချိတယ်။ သူတို့က’ ရှုပ်ထွေးသော ပုံစံများနှင့် လေးထန်သော ဝန်ဆောင်မှုများအတွက် တည်ငြိမ်ပြီး ဘေးကင်းပါ။ ၎င်းတို့ဟာ တံတားဆောက်လုပ်ခြင်း ဒါမှမဟုတ် တံတားလမ်းခြေလုပ်ခြင်းလို ခက်ခဲတဲ့ အလုပ

စက်ကားစနစ်ကို ရွေးချယ်စဉ်တွင် စဉ်းစားရန် အဓိကအချက်များ

မှန်ကန်တဲ့ ခြေစက်ကို ရွေးချယ်ခြင်းက ဘေးကင်းမှုကို အာမခံပေးပြီး ငွေကို ချွေတာပေးတယ်။ ဤတွင် စဉ်းစားရန် အဓိက အချက်များဖြစ်သည်။

- စီမံကိန်းအရွယ်အစားနှင့် ရှုပ်ထွေးမှုကြီးမားတဲ့ ဒါမှမဟုတ် ရှုပ်ထွေးတဲ့ စီမံကိန်းတွေဟာ Ringlock ခြေစက်လို မော်ဂျူးစနစ်တွေလိုပါတယ်။ GOWE မှ M48 နှင့် M60 တို့သည် လေးထန်သော ဝန်များနှင့် ရှုပ်ထွေးသော ဒီဇိုင်းများကို ကိုင်တွယ်သည်။

- ပစ္စည်းလိုအပ်ချက်များသံမဏိဟာ ခိုင်မာပြီး ရှည်ကြာပါတယ်။ အလူမီနီယံဟာ ပေါ့ပြီး လှုပ်ရှားဖို့ လွယ်ကူပါတယ်။ သစ်သားသို့မဟုတ် ဝါး scaffolds အစဉ်အလာအလုပ်များအတွက်အလုပ်လုပ်ပေမဲ့’ t ဟာ ခိုင်မာတယ်။

- ဘတ်ဂျက် ကန့်သတ်ချက်များဘောင်ပုံရှေ့ခုံဟာ အလုပ်ငယ်တွေအတွက် စျေးပေါပါတယ်။ Ringlock သို့မဟုတ် Cuplock ဟာ ပိုကုန်ကျပေမဲ့ အချိန်ကြာလာတာနဲ့ ပြန်လည် အသုံးပြုခြင်းနဲ့ ငွေကို ချွေတာတယ်။

- လုံခြုံရေးစံနှုန်းများအလုပ်သမားများကို ဘေးကင်းစေရန် EN12811 ကဲ့သို့သော စည်းမျဉ်းများကို လိုက်နာပါ။

- လှုပ်ရှားမှုလိုအပ်ချက်များဘီးတွေပါတဲ့ မိုဘိုင်းရှိ စက်ကွင်းတွေဟာ နေရာတစ်ခုကို လှုပ်ရှားဖို့ ကောင်းပါတယ်။

- ပတ်ဝန်းကျင်အခြေအနေများ: သံချောက်ကို ရပ်တန့်ရန် စိုစွတ်သော သို့မဟုတ် ဆားရှိသော နေရာများတွင် ပူနေသော သွပ်ရည်စွမ်းထားသ

GOWE Group: သင့်ရဲ့ ယုံကြည်စိတ်ချရတဲ့ မိတ်ဖက်

Gowe ခေါင်းဆောင်မှုတွေဟာ ရေခြေတွေမှာပါ။ နှစ် ၃၀ ကျော် အတွေ့အကြုံရှိပါတယ်။ ကျွန်တော်တို့မှာ မူပိုင်ခွင့် ၄၆၀ ရှိပါတယ်။ ကျွန်ုပ်တို့’ ကမ္ဘာတစ်ဝှမ်းမှာ စီမံကိန်း ၁၀၀၀၀ ကျော်မှာ အလုပ်လုပ်ခဲ့တယ်။ GOWE သည် မတူညီသော လိုအပ်ချက်များအတွက် လက်ခြေအမျိုးအစားများစွာကို ကမ်းလှမ်းသည်။ သုတေသန၊ ထုတ်လုပ်မှု၊ ရောင်းချမှု၊ ငှားရမ်းမှု၊ တည်ဆောက်မှုနဲ့ စီမံခန့်ခွဲမှုတွေကို ကျွ ကျွန်တော်တို့ရဲ့ အဖွဲ့ဟာ အစကနေ အဆုံးအထိ အပြည့်အဝ ဖြေရှင်းနည်းတွေ ပေးတယ်။ စီမံကိန်းတွေဟာ ချောမွေ့စွာ ပြုလုပ်နေတာကို သေချာစေပါတယ်။ ဘေးကင်းလုံခြုံပြီး စမတ်ဖြစ်တဲ့ ရေခြေအတွက် GOWE ကို ရွေးချယ်ပါ။ ကမ္ဘာတစ်ဝှမ်းက စာချုပ်သူတွေကို ရည်မှန်းချက်တွေကို ဖြည့်ဆည်းပြီး အောင်မြင်ဖို့ ကူည

FAQ များ

မေး: ဆောက်လုပ်ရေးတွင် အသုံးပြုသော အဓိကရေခြေအမျိုးအစားများ ဘာတွေလဲ။

ဖြေ: အဓိကအမျိုးအစားများတွင် ပြွန်နှင့် ချိတ်ဆက်စက်၊ စနစ်ခြေစက်၊ ဘောင်ခြေစက်နှင့် ရပ်တန့်ထားသော ခြ တစ်ခုစီဟာ စီမံကိန်း လိုအပ်ချက်တွေကို ကိုက်ညီပါတယ်။

မေး: ကျွန်ုပ်၏ စီမံကိန်းအတွက် မှန်ကန်သော ရေခုံကို ဘယ်လိုရွေးချယ်ရမလဲ။

ဖြေ: စီမံကိန်းအရွယ်အစား၊ အမြင့်၊ ဝန်နဲ့ ရာသီဥတုကို ကြည့်ပါ။ အကောင်းဆုံး အမျိုးအစားကို ရွေးချယ်ဖို့ ရေခြေကျွမ်းကျင်သူနဲ့ စကားပြောပါ။

မေး: စက်ကားများကို အသုံးပြုစဉ် ဘယ်လုံခြုံရေးအစီအစဉ်များကို စဉ်းစားသင့်သလဲ။

ဖြေ: လေ့ကျင့်ထားတဲ့ အလုပ်သမားတွေကို အသုံးပြုပါ။ မကြာခဏ စစ်ကြည့်ပါ။ ကာကွယ်ရေးကိရိယာတွေကို ထည့်ပြီး PPE လို လုံခြုံရေးကိရိယာတွေကို သုံးပါ။

မေး: ထူးခြားတဲ့ ဆောက်လုပ်ရေး စီမံကိန်းတွေအတွက် စက်ဖောက်ကို စိတ်ကြိုက်ပြုနိုင်လား။

ဖြေ: ဟုတ်ပါတယ်။ စနစ်များစွာကို အထူးသို့မဟုတ် ရှုပ်ထွေးတဲ့ အလုပ်တွေနဲ့ ကိုက်ညီဖို့ ကွဲပြားခြားနားတဲ့ အစီအစဉ်တ

မေး: GOWE Group သည် နိုင်ငံတကာ ဖောက်သည်များအား စက်ဖော်လိုအပ်ချက်များနှင့် ပတ်သက်၍ ဘယ်လိုထောက်ပံ့

ဖြေ: GOWE သည် တရုတ်၊ အရှေ့တောင်အာရှ၊ ဥရောပနှင့် မြောက်အမေရိကရှိ ဖောက်သည်များအတွက် ဒီဇိုင်းအကြံပေးချက်၊ ထုတ်က