Modern construction calls for speed, accuracy, and cost savings. Aluminum formwork has become a game-changer, offering clear benefits over older timber and steel methods. At GOWE, we produce top-quality aluminum formwork systems that excel in residential, commercial, and infrastructure projects. This blog highlights five major advantages of aluminum formwork and explains why contractors and developers globally prefer it.

What Makes Aluminium Formwork Faster Than

Traditional Systems?

How does the lightweight design speed up construction cycles?

Aluminum formwork weighs much less than timber or steel, making it easier to handle and quicker to set up. A key advantage is its ability to shorten floor cycle times, often finishing one floor in 4 to 5 days. Traditional systems may take twice as long.

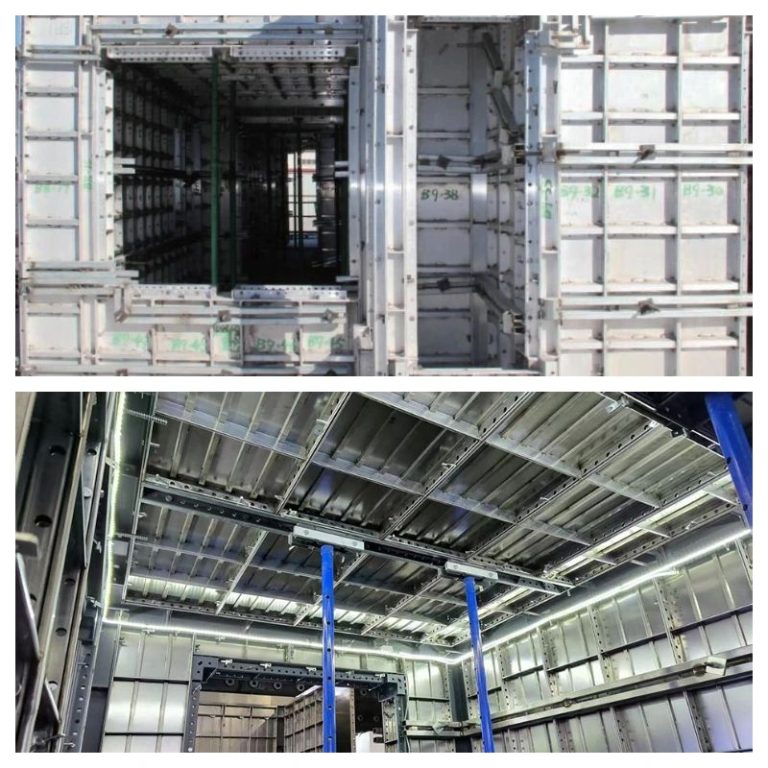

At GOWE, our Aluminium Formwork System for Residential Projects features a user-friendly design and efficient panels. The lightweight build reduces worker strain, cuts crane usage, and streamlines site operations.

What are the typical slab cycle time savings?

Clients using GOWE’s modular aluminum formwork report slab cycle times reduced by up to 50% compared to timber methods. Faster floor completion leads to significant cost savings over a project’s lifespan.

The pre-planned panel layout minimizes on-site adjustments, lowering errors and delays. This proves especially valuable in large housing projects across Asia and the Middle East.

In India, a partner built a 15-storey residential tower in record time, cutting project duration by 30%. They credited our quick-assembly modular panels and built-in support system.

In Southeast Asia, our formwork supported a 25-tower mixed-use project, achieving a steady 4-day slab cycle across all towers. The project lead praised the system’s consistency for enabling smooth, overlapping construction phases.

Why Is Aluminium Formwork More Durable and Reusable?

How many times can aluminum panels be reused?

Traditional plywood formwork lasts for 10–20 uses before wearing out. GOWE’s aluminum formwork, however, can be reused up to 250 times with proper care, making it a smart long-term choice.

What maintenance is needed to extend lifespan?

Little upkeep is needed. Cleaning panels after each pour and using anti-stick coatings keep them in good shape.

Our Aluminium Formwork System for High-Rise Buildings uses anodized panels for extra rust protection and lasting strength.

Contractors on multi-tower housing projects have reused GOWE’s aluminum formwork across all stages without losing quality or concrete finish.

Our CNC-machined parts ensure a precise fit and steady performance, even in repetitive tasks.

In the UAE, a developer reused our system for six residential towers over five years. Despite sandstorms and humidity, the panels held their shape and look with minimal care.

How Does Aluminium Formwork Deliver a Smoother Concrete Finish?

What precision and surface quality?

Aluminum formwork creates a tight, accurate mold for smooth concrete surfaces with minimal gaps. This cuts down on plastering or extra finishing work.

Our aluminum molds are crafted with automated tools for exact sizing and smooth contact, ensuring even wall thickness and straight alignment.

How much plastering can you skip?

With GOWE’s systems, like the Wall and Slab Formwork System, clients have cut plastering by up to 90%. The clean finish allows direct painting or decor after light prep.

This high-quality finish is especially valued in commercial projects where looks matter.

In Malaysia, a commercial office tower project used our aluminum formwork for Class A concrete finishes, saving over 20% on interior finishing costs.

In Singapore, a luxury residential complex skipped plastering entirely across 300+ units, letting painters start after a thin skim coat.

How Does Aluminium Formwork Save Cost Over the Long Term?

What is the break-even point compared to timber or steel?

The upfront cost is higher, but aluminum formwork pays off over time. When reused across projects, it becomes far cheaper. The break-even point typically comes within 3–5 projects.

Our systems are built for reuse across multiple sites, ideal for developers handling housing or commercial portfolios.

How do labor and material savings factor in?

Quicker construction lowers overhead costs. Precise parts reduce the need for skilled workers, cutting man-hours. GOWE’s systems simplify assembly, reducing mistakes and rework.

Partners in Africa and Southeast Asia report up to 25% savings on project costs with GOWE’s aluminum systems, especially for repetitive layouts and large housing projects.

Is Aluminium Formwork Better for Sustainable Construction?

How does reusability reduce construction waste?

Each reusable aluminum panel saves trees that would be used for timber formwork. Hundreds of reuse cycles sharply cut material waste.

GOWE prioritizes eco-friendly production, and our products are fully recyclable at the end of their life.

Can aluminum formwork contribute to green building certifications?

Yes, aluminum formwork is recyclable and supports LEED and other green certifications. At GOWE, we promote sustainable building. Our systems have aided green-certified projects in Southeast Asia, the Middle East, and Africa.

GOWE’s aluminium formwork systems have been essential for completing large infrastructure projects swiftly. At the Beijing Daxing International Airport, our solutions supported rapid and accurate construction work. They met tight schedules and strict quality standards for a leading global transport hub. Similarly, at the Hangzhou Airport Rail Express Wuchang Training Base, our systems ensured smooth connection of complex structural components. This sped up building and maintained consistency. These projects highlight GOWE’s reliable expertise in assisting significant developments with durable, reusable, and precise formwork technology.

FAQ

Q: Is aluminium formwork suitable for all types of building projects?

A: Yes, it performs well for residential, commercial, and high-rise structures. GOWE provides customized systems for various needs.

Q: How long does it take to train workers to use aluminium formwork?

A: Workers require about 2–3 days of training to learn our simple panel layout and locking system.

Q: Can GOWE’s aluminium formwork be customized for complex designs?

A: Yes, we offer tailored designs for curved walls, unique slabs, and other architectural requirements.

Q: Is aluminium formwork compatible with precast or cast-in-place methods?

A: Yes, our systems are versatile and work with both construction methods.

Q: How does aluminium formwork perform in hot or humid climates?

A: GOWE’s anodized panels withstand rust and heat damage, making them suitable for challenging climates in Asia, Africa, and the Middle East.