Industry Challenges in Formwork Stability and Safety

The Importance of Material Selection in Construction

In construction, picking the right materials for formwork is a big deal for keeping things steady and safe. A formwork flop can spell disaster—think worker injuries, project holdups, or ballooning costs. Often, the trouble starts when materials don’t match the job’s needs. Choosing the right stuff boosts stability, keeps workers out of harm’s way, and makes the whole project run smoother. GOWE steps in as a one-stop shop, dishing out expertise from research to on-site work. Their know-how ensures materials fit the project like a glove.

Common Issues Faced in Formwork Stability and Safety

Formwork faces some tough hurdles. Materials can bend under heavy loads, struggle with wet or hot weather, or be a pain to handle if they’re too heavy. Any of these can throw safety out the window and slow down the job.

Core Material Parameters Influencing Stability

Strength and Stiffness

The Role of Structural Integrity in Load-Bearing Capacity

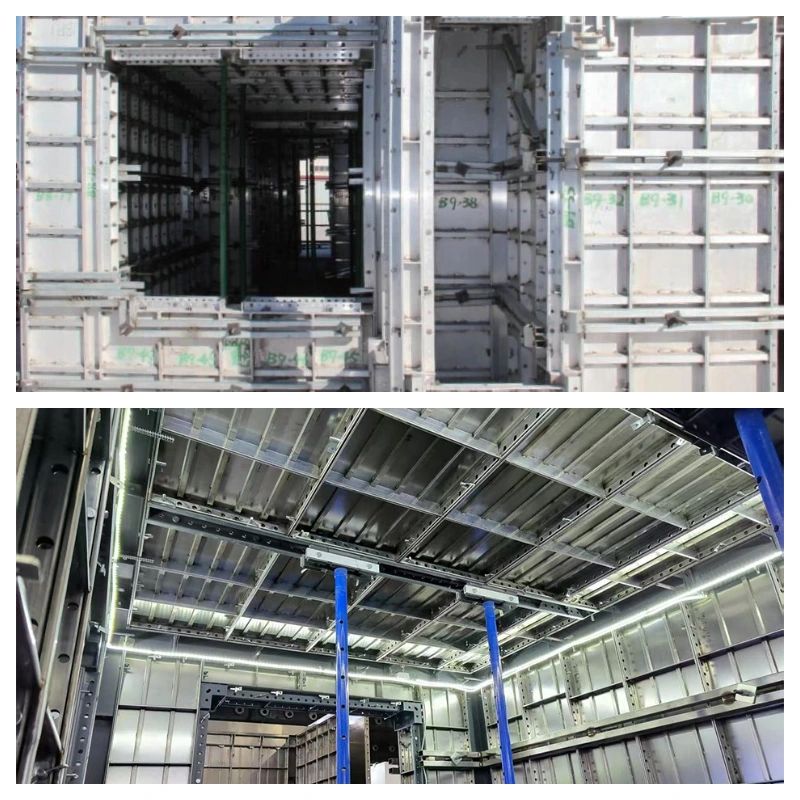

Strength is the backbone of any formwork material. It decides whether the stuff can hold up under heavy concrete pours without buckling. Steel formworks, for example, are champs at handling big loads, perfect for heavy-duty jobs. Timber, though, can cave under the same pressure because it’s not as tough. GOWE’s aluminum formwork system is a solid pick for RCC load-bearing structures. It’s got the muscle to cast walls and slabs in one go while staying rock-steady.

How Stiffness Affects Deformation Under Load

Stiffness matters just as much. It keeps materials from bending or twisting when concrete pushes against them. Flimsy stuff like timber can warp or sag, messing up alignments or even collapsing. Aluminum formworks shine here with their tight tolerances and steady shape, especially on multi-story builds. They don’t budge, keeping floors consistent.

Weather Resistance and Durability

Impact of Environmental Conditions on Material Performance

Weather can be a real bully to formwork materials. Humidity, temperature swings, or salty air can chew up the wrong stuff. Timber soaks up water, swells, or rots. Steel without protection rusts fast. GOWE’s aluminum alloy formworks laugh off corrosion, making them a top choice for wet or coastal sites where durability is everything.

Long-Term Durability and Its Effect on Safety

Durable materials mean safer sites. Stuff that wears out fast raises the odds of a breakdown during construction. Aluminum lasts for ages, cutting the risk of accidents and saving cash on replacements. GOWE’s aluminum systems mitigate these risks through inherent corrosion resistance.

Weight and Construction Efficiency

Balancing Lightweight Materials with Structural Stability

Lightweight materials like aluminum make life easier without skimping on strength. They’re a breeze to handle compared to hefty steel forms that need extra muscle to move. GOWE’s aluminum formwork systems speed up construction big time. They’re light but tough, letting crews zip through assembly while keeping things solid.

Influence of Material Weight on Handling and Installation

Heavy materials are a recipe for trouble. They increase the chance of accidents when moving or setting up. Aluminum’s lighter weight cuts those risks and speeds up the process between pours.

Material Failure Modes and Associated Safety Risks

Common Failure Patterns in Formwork Materials

Cracking, Warping, and Deformation Risks

Some materials crack under stress, especially brittle ones. Wood often warps when wet, throwing off the whole formwork setup. These issues mess with alignment and can make the system useless.

Corrosion and Its Impact on Metal Formworks

Corrosion eats away at metal forms, weakening them over time. Steel without a good coating is especially vulnerable. GOWE’s aluminum systems dodge this with their natural rust resistance.

Safety Hazards Arising from Material Failures

Worker Safety Concerns During Construction

When materials give out, workers are in the line of fire. Falling chunks or collapsing forms can lead to serious injuries or worse.

Project Delays Due to Material Instabilities

Shaky materials mean constant fixes or swaps during construction. This stalls the job and racks up costs for wasted time and resources.

GOWE Solutions Tailored for Optimal Results

GOWE crafts solutions that fit each project’s needs—think weather, loads, and budgets. Their mix of brainy engineering and top-tier manufacturing ensures every job hits peak stability and safety. They offer lightweight aluminum systems for quick commercial builds, beefy steel for heavy loads, classic timber for flexible looks, and slick plastic systems that shrug off corrosion with barely any upkeep. These options make buying easy while meeting global standards. With GOWE’s know-how in research, production, and on-site work, contractors can tackle tough formwork challenges with confidence.

Matching Materials to Engineering Scenarios

Factors to Consider for Specific Construction Projects

High-Rise Buildings: Prioritizing Strength and Lightweight Design

High-rise projects are a beast to tackle. You need materials that are strong but not a pain to haul up dozens of floors. GOWE’s aluminum formwork systems are a perfect match. They’re tough enough for serious loads yet light enough to move easily. This balance keeps workers safe and speeds up the job. Their precision ensures every floor stays spot-on, making it easy to slot in plumbing or electrical fittings. Plus, aluminum’s monolithic setup spreads loads evenly, handling wind or quakes like a pro.

Bridges and Tunnels: Emphasizing Durability Under Harsh Conditions

Bridges and tunnels face brutal conditions—think wet, salty air or wild temperature swings. Durability is non-negotiable. GOWE’s aluminum alloy formworks stand up to corrosion, perfect for coastal or humid spots. Steel forms work for heavy-duty jobs like bridges, but they need coatings to fight rust. GOWE’s tight manufacturing standards ensure their steel holds up under pressure.

Selecting the Right Materials for Diverse Applications

Temporary vs. Permanent Formwork Solutions

Temporary or permanent formwork depends on the project and budget. Timber is great for quick, cheap setups because it’s easy to shape. But it warps in wet conditions, so it’s not a long-term star. For permanent jobs, aluminum or plastic forms are the way to go. GOWE’s plastic systems resist corrosion and need little upkeep, making them ideal for lasting stability.

Customizing Materials Based on Regional Climate Conditions

Local weather calls the shots on material picks. High-humidity zones need stuff that won’t soak up water, like aluminum or plastic. Places with big temperature swings need materials that don’t expand or shrink much. GOWE designs to global standards, tailoring solutions for any climate. Their custom options tackle local challenges head-on, ensuring top performance wherever you build.

GOWE‘s Comprehensive Solutions for Formwork Stability and Safety

Advanced Research and Development in Material Innovation

GOWE pours big bucks into research to push formwork tech forward. Their focus on new materials leads to systems built for today’s tough construction demands. Using fancy tools like CAD/CAM software, they turn complex designs into practical formwork with pinpoint accuracy. Their high-tech factories, packed with precise CNC machines, shape components fast and flawlessly.

High-Quality Production Standards for Reliable Formworks

Quality is GOWE’s middle name. They start with strict checks on raw materials, only using stuff that passes tough tests for strength and durability. During production, skilled engineers keep an eye on every step to catch any flaws. Final inspections match global standards, so only the best gear ships out.

Tailored Solutions for Contractors Across Various Regions

No two projects are the same, and GOWE gets that. They offer custom solutions, tweaking sizes or materials to fit unique challenges. From planning to building, their team works hand-in-hand with contractors to nail stability and safety. Their expertise covers research, production, sales, leasing, and on-site support, making them a full-package partner.

FAQ

Q: How does material selection affect formwork stability?

A: Choosing materials like aluminum impacts stability due to its strength-to-weight ratio. It handles concrete pressure without breaking a sweat, keeping structures solid.

Q: What role does aluminum play in formwork safety?

A: Aluminum’s light but tough nature boosts safety. It lowers collapse risks and makes setup easier, cutting down on-site accidents.

Q: How do different formwork materials compare in terms of durability?

A: Aluminum beats wood with its corrosion resistance and long life. It outlasts traditional materials in tough conditions.

Q: Why is quality control important in material selection for formwork?

A: Tight quality checks ensure materials meet safety standards. This prevents failures that could spark accidents on-site.

Q: Can material selection impact the efficiency of formwork systems?

A: Yes, lightweight materials like aluminum speed up setup and handling. This makes projects faster and smoother overall.