Why Choose China, and Why Is It So Challenging?

As an international buyer, you may find yourself torn between the unbeatable cost advantages of Chinese manufacturing and the uncertainties that come with it. On one hand, China stands as the world’s leading scaffolding production hub, backed by strong industrial clusters, a complete supply chain, and proven technical capabilities. On the other hand, challenges remain:

- A massive number of suppliers with varying quality standards

- Complex certification systems

- Communication barriers due to language and cultural gaps

- Risks of delayed delivery or inconsistent quality

This guide aims to clear the fog. By the end, you’ll have a systematic roadmap to help you source, evaluate, and secure reliable scaffolding suppliers in China—turning risks into opportunities and building strong long-term partnerships. For those looking to streamline their sourcing efforts, GOWE offers a range of solutions to help you find trustworthy suppliers and ensure smooth transactions.

Step 1: Define Your Needs—The Foundation of Every Purchase

Before contacting suppliers, you must first clearly define your own requirements. This ensures efficient sourcing and helps filter out unqualified vendors quickly.

Technical Specifications of Scaffolding

- Type Selection: Depending on your project needs, choose between ringlock scaffolding (the current trend), cuplock scaffolding, frame scaffolding, or others.

- Material & Processing: Common steel grades include Q235 vs Q355; galvanization quality (e.g., hot-dip thickness) directly affects durability.

- Certification Standards: Identify what’s required for your target market, such as EN 12811 (Europe), AS/NZS 1576 (Australia/New Zealand), or OSHA (United States).

Commercial & Logistical Requirements

- Order Quantity: Trial orders vs. annual bulk demand.

- Target Price Range: Define a realistic budget to avoid mismatched negotiations.

- Trade Terms: Decide on FOB (standard), CIF, or even DDPdepending on your project.

Pro Tip: The clearer your requirements, the faster you’ll identify suitable suppliers and the less time you’ll waste on unfit candidates. For advanced tools and advice on supplier selection, explore more on Gowe.

Step 2: Efficient Sourcing—Where to Find Potential Suppliers?

China offers rich resources, but the real challenge lies in navigating the ocean of suppliers. Here’s how to locate quality options:

Regional Clusters:

- Hebei & Tianjin– Large-scale steel pipe and ringlock scaffolding production is cost-effective.

- Jiangsu & Shandong– Strong welding expertise and many export-oriented enterprises.

- Guangdong & Zhejiang– Higher standardization, stronger focus on EU & AU certifications.

Complete Supply Chain:

- Upstream: Raw steel pipes, castings.

- Midstream: Galvanization, welding, stamping, surface treatment.

- Downstream: Packaging, logistics, and port handling for FOB, CIF, or DDP shipments.

Global Export Hub: China is the most prominent scaffolding exporter worldwide, serving Asia, the Middle East, Africa, Europe, and the Americas, with many suppliers already compliant with ISO, EN, AS/NZS, and OSHA

B2B Platforms (Broad Search)

- Popular platforms: Alibaba International, Made-in-China.

- Advanced Tips: Use targeted keywords like “EN 12811 ringlock scaffolding”, filter “Scaffolding Suppliers,” review factory videos, and check certifications. As one of the leading manufacturers and suppliers of Formwork and Scaffolding systems, GOWE has integrated R&D, production, sales, leasing, construction, and operation of construction Formworks, Scaffolding, Steel structures, Bridge and Tunnel equipment, Building materials, and more.

Search Engines (Deep Search)

- Combine Chinese & English keywords: “盘扣脚手架 生产厂家”or “scaffolding manufacturers in China”.

- Look for suppliers with multilingual websites, technical whitepapers, or case studies.

Trade Fairs & Industry Associations (High-Value Leads)

- China International Building Trade Fair– direct access to top manufacturers.

- Construction Safety Associations– membership lists usually include more compliant and reliable companies.

Step 3: Strict Screening and Evaluation—Separating Gold from Gravel

Once you’ve built a supplier shortlist, it’s time for due diligence.

Verify Business Credentials

- Business license: Confirm company legitimacy and registered capital.

- Quality management certification: ISO 9001is a minimum requirement.

- Product certification: Look for third-party test reports(SGS, TUV).

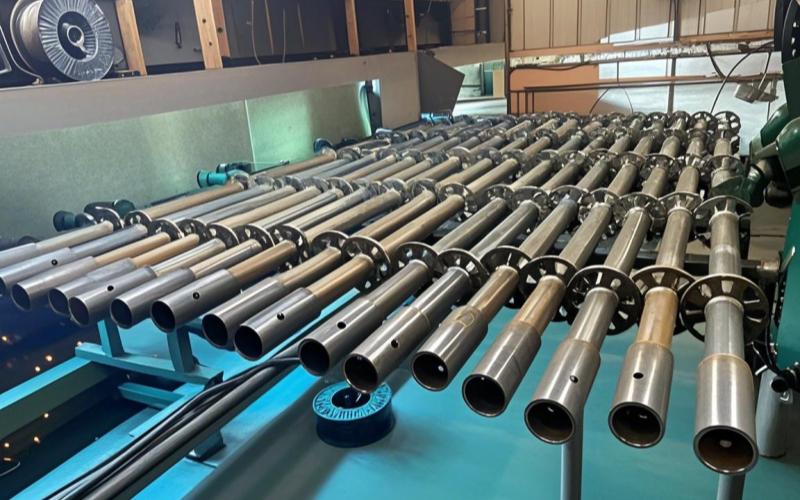

Assess Production Capacity

- Monthly production capability: Can they meet your order volume?

- In-house vs outsourced production: Especially for key processes like galvanization.

- Evidence: Ask for factory tour videos, equipment lists, and workshop photos.

Evaluate Quality Control Systems

- Ask about inspection standards: IQC (Incoming), IPQC (In-Process), FQC (Final).

- Smart Question: “How do you ensure galvanization layer uniformity and thickness?”

Step 4: Deep Communication and Sampling—Testing the Real Capabilities

Professional Inquiry

Send a detailed inquiry with your specifications from Step 1 and observe how professional and timely their response is.

Sample Evaluation

- Never skip sampling: “No sample, no bulk order.”

- Test sample quality: Dimensions, weight, galvanization, welds.

- Independent lab testing is recommended.

Communication & Service Attitude

- Do they have an international sales team?

- Are they proactive problem solvers or dismissive?

- Their attitude reflects their long-term reliability.

Step 5: Final Verification and Negotiation—Securing the Right Partner

Factory Audit (Highly Recommended for Large Orders)

- On-site visit or hire a third-party audit firm (SGS, Intertek).

- Check if production environment and quality processes match claims.

Price and Terms Negotiation

- Understand cost structure: raw material, processing, galvanization, packaging, margin.

- Negotiate with quality as the baseline—not the lowest price.

- Payment terms: Favorable options include 30% deposit and 70% against B/L copy.

Contract Review

Ensure the contract specifies:

- Technical parameters

- Quality standards

- Delivery time

- Penalty for delays or non-conformance

Conclusion: Minimize Risk, Maximize Value

The roadmap to sourcing scaffolding in China can be summarized as:

Define Needs → Efficient Sourcing → Strict Screening → Deep Verification → Careful Contracting.

China’s manufacturing ecosystem provides unparalleled advantages, but long-term success comes from selecting trustworthy partners rather than just chasing the lowest bid. Your upfront effort will translate into smoother cooperation, reduced risks, and sustainable cost savings.

With a systematic approach, you can confidently navigate China’s supply chain and transform “Made in China” into your project’s competitive edge. If you’re looking for a hassle-free sourcing experience, Gowe offers top-notch tools to connect you with reliable, certified suppliers in just a few clicks.

Frequently Asked Questions (FAQs)

1. Why is China the leading source for scaffolding?

Because China has strong industrial clusters, complete supply chains, and cost advantages that allow it to supply global markets efficiently.

2. How do I ensure scaffolding meets international safety standards?

Always request certification reports such as EN 12811, AS/NZS 1576, or OSHA compliance, and verify them with independent labs or third-party inspection agencies.

3. Is it safe to order scaffolding directly from Alibaba or Made-in-China?

Yes, but only after thorough due diligence: verify certifications, request samples, and consider third-party inspections.

4. What’s the most common issue international buyers face?

Quality inconsistencies and delayed delivery. Both can be minimized by proper screening, sampling, and clear contract terms.

5. Should I visit the factory before placing a large order?

Absolutely. A factory audit (in-person or via third party) is the most reliable way to confirm supplier capabilities.

6. What payment terms are considered safe for overseas buyers?

A typical structure is 30% upfront deposit and 70% balance against Bill of Lading copy. For extra security, consider using Letter of Credit (L/C).