In the world of nuclear infrastructure, where the slightest miscalculation can have dire consequences, precision and reliability are non-negotiable. Imagine a scenario where a single misplaced millimeter could lead to a costly reactor shutdown or compromise safety. The construction of critical elements, such as the Return Water Pipeline System in the Utility Tunnel, presents unique engineering challenges, demanding solutions that push the boundaries of conventional construction. For the pivotal San’ao Nuclear Power Plant project, the complex, double-curved design of the Return Water Pipeline System in Utility Tunnel presented one such formidable challenge. The question arose: how to build a formwork system that could accurately and efficiently create these sophisticated shapes while withstanding the immense pressures of concrete pouring and meeting the stringent, long-lasting quality standards of a nuclear facility?

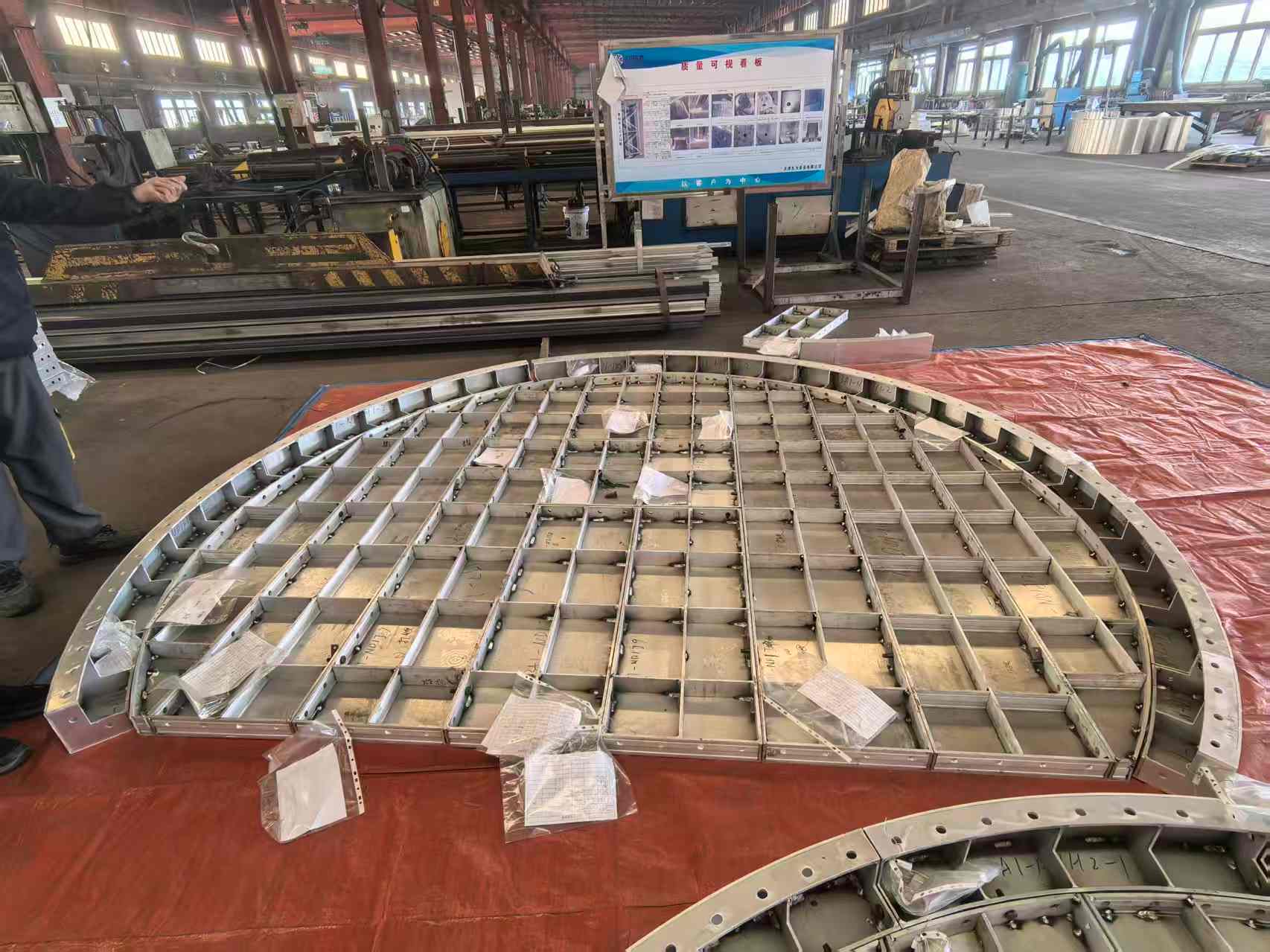

The answer, pioneered by GOWE Group, marked a potential national first: the implementation of a double-curved aluminum inner formwork. This decision was not merely a material substitution; it was a fundamental re-imagining of construction methodology for one of the most demanding applications imaginable.

Why Choose Aluminum When Lives Depend on Steel?

Traditionally, large-scale infrastructure projects have relied heavily on steel or timber for formwork. While robust, these materials come with significant limitations for a project of this complexity. Steel is incredibly heavy, requiring extensive use of heavy machinery for placement and adjustment, which slows down progress and increases costs. Its rigidity also makes it difficult and expensive to fashion into the seamless double curves required. An example from a recent project highlights this issue—a steel formwork delay resulted in a month-long postponement, which pushed the project over budget due to the need for specialized machinery and labor. Wood, though more malleable, lacks the consistency and durability needed for the repeated pours and perfect surface finish demanded in a nuclear setting. A case in point was when timber warped under the strain of environmental conditions, resulting in subpar finishes that required costly repairs.

For owners racing against outage windows and facing cost overruns, schedule slips, and inspection failures, GOWE Group’s selection of aluminum was a strategic engineering decision rooted in addressing these urgent challenges. The superior properties of aluminum offer direct benefits to overcome these pressures:

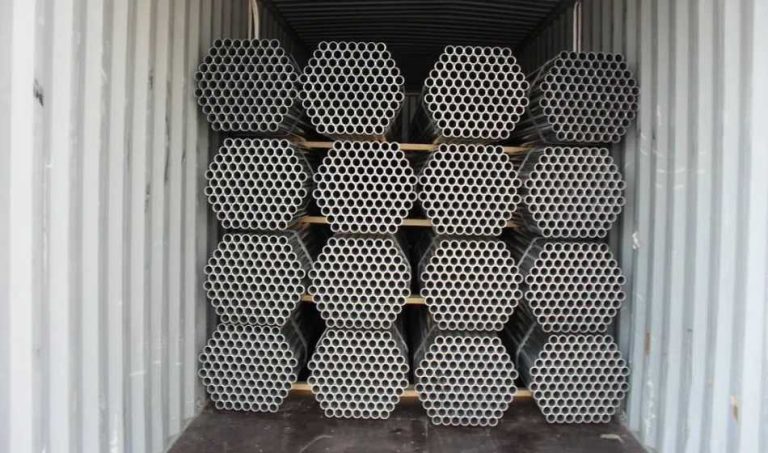

- High Strength-to-Weight Ratio: Aluminum formwork is significantly lighter than its steel counterpart, enabling faster installation and repositioning with smaller cranes, which directly boosts on-site efficiency and enhances worker safety.

- Exceptional Malleability: Aluminum can be expertly fabricated into the complex, flowing double-curved geometries essential for the tunnel’s hydraulic efficiency. This ensured a perfect geometrical translation from the digital model to the finished concrete structure.

- Superior Durability and Stability: Resistant to corrosion, the aluminum forms maintain their dimensional integrity and smooth surface finish over multiple uses, even when exposed to the harsh environment of fresh concrete, guaranteeing a consistent, high-quality result every time.

Conquering the Double Curve: A Symphony of Design and Digital Fabrication

Here’s how we conducted that symphony, note by digital note, preparing our minds for a technical deep dive that revealed the intricacies of digital precision and creative engineering.

Creating a large-scale, load-bearing double-curved structure is one of the most complex tasks in civil engineering. The margin for error is virtually zero, as even a minor misalignment could result in repair costs exceeding hundreds of thousands of dollars or pose potential safety risks related to radiation containment. GOWE Group’s success hinged on a fully integrated digital process that bridged the gap between ambitious design and physical reality.

- High-Fidelity 3D Modeling & BIM Collaboration: Our process began with the creation of a precise, high-resolution Building Information Modeling (BIM) model of the tunnel section. This model served as the single source of truth, enabling clash detection and seamless coordination with other disciplines, such as rebar detailing and MEP (Mechanical, Electrical, and Plumbing) systems, before any metal was cut.

- Digital Prototyping and Simulation: We employed advanced digital twin technology to create a virtual replica of the formwork system. This allowed our engineers to simulate the entire assembly and concrete pouring process in a risk-free environment. Potential issues, from sequencing errors to structural stress points, were identified and resolved digitally, preventing costly delays and rework on-site.

- Precision Digital Fabrication: The approved digital designs were sent directly to state-of-the-art CNC (Computer Numerical Control) machinery. This technology translated the complex digital curves into physical aluminum components with sub-millimeter accuracy. Each panel was not just a piece of metal; it was a digitally perfected component designed to interlock perfectly with its neighbors, creating the seamless, continuous double-curved surface required.

The Impact: Quantifying a Pioneering Decision

The deployment of GOWE Group’s double-curved aluminum inner formwork at the San’ao Nuclear Power Plant site yielded transformative results, setting a new benchmark for future projects.

- Dramatic Efficiency Gains: The lightweight nature of the aluminum system led to an estimated 30% reduction in installation time compared to a hypothetical steel solution. This efficiency leap effectively added more time to the project timeline, almost like building an extra month into the schedule. This significant acceleration directly contributed to keeping the project’s critical path on schedule.

- Optimized Project Economics: The reduced reliance on heavy-lift cranes and the decreased labor requirements translated into substantial cost savings. Furthermore, the durability of the aluminum ensures it can be reused across multiple pours and on future projects, enhancing its long-term value.

- Uncompromised Safety and Quality: The easier handling of lighter components minimized on-site safety risks associated with heavy lifting. Most importantly, the system’s precision resulted in a flawless concrete finish with the exact hydraulic properties designed by the engineers, ensuring the long-term performance and safety of the power plant’s cooling system.

- A New National Standard: This project serves as a powerful case study, proving the viability and superiority of aluminum for complex formwork applications. It has set a new precedent, encouraging engineers and project owners across China and beyond to consider innovative materials for overcoming their most daunting structural challenges. This innovation offers a glimpse of what could be achieved in your next bid or project. Imagine the competitive edge in efficiency and cost-effectiveness such advances could bring to your plans.

Conclusion: Building the Future, One Innovation at a Time

The San’ao Nuclear Power Plant project is more than an energy infrastructure milestone; it is a testament to how innovative construction techniques can redefine what is possible. GOWE Group is proud to have been at the forefront of this innovation, turning a complex challenge into a resounding success through engineering excellence, digital integration, and the courage to pioneer a new path.

This project underscores our core belief: the future of construction lies in smarter, lighter, and more precise solutions.

Are you facing a unique structural or geometric challenge on your upcoming project? Partner with innovators who see beyond conventional solutions. By choosing GOWE Group, you gain not only a strategic partner but also the assurance of cost certainty, schedule relief, and regulatory confidence. Imagine unlocking new efficiencies and achieving your project goals with precision and reliability. Contact GOWE Group today to engineer the impossible.