Today, construction companies need to work faster, safer, and with fewer workers. As buildings get taller and projects become more complex, traditional scaffolding is no longer enough. It takes too much time, uses too much material, and can be unsafe at high heights.

To solve these problems, the

Electric Mast Climbing Work Platform (MCWP) has become a modern tool used around the world. It helps workers reach high places easily and safely, which means for you that workers can complete projects with reduced risk of accidents and delays. This technology enhances the speed and quality of façade construction, so your crews can hand over façades weeks earlier and earn client bonuses, which ultimately means more efficient project completion and higher profitability for you.

What Is an Electric Mast Climbing Work Platform?

An electric MCWP is a platform that moves up and down along a building using an electric motor. Instead of building a large scaffolding system around the building, the MCWP climbs on a mast and provides a wide, stable space for workers to stand on.

The platform can move smoothly, carry heavy loads, and adjust its length to fit different types of buildings. Because it climbs automatically, it saves time and reduces the number of workers needed on-site.

Why We Need This Technology

Construction teams face many challenges today:

1. Labor Is Expensive

Traditional scaffolding requires a large number of workers to build and dismantle. MCWPs need far fewer workers.

2. Buildings Are Getting Taller

Tall buildings need safer and more reliable platforms that can reach high places without risk.

3. Too Much Material Waste

Old-style scaffolding uses tons of steel. MCWPs use significantly less material, which saves money and helps protect the environment.

4. Work Needs to Be Faster

Modern building schedules are tight. MCWPs help workers complete façade jobs more efficiently and keep projects on track.

How the MCWP Works

The MCWP works with three main systems:

1. Rack-and-Pinion Drive

An electric motor turns a gear that climbs up a metal rack on the mast.

2. Dual-Motor Power

The platform is equipped with dual motors, ensuring continued operation even if one motor fails to function. This built-in redundancy not only minimizes potential downtime, keeping crews productive, but it also provides peace of mind to site managers and insurers regarding liability and operational reliability.

3. Safety System

The platform has many safety features:

- Anti-fall device

- Auto-leveling system

- Emergency stop

- Limit switches

- Manual lowering during a power failure

These safety tools help keep workers secure at all times.

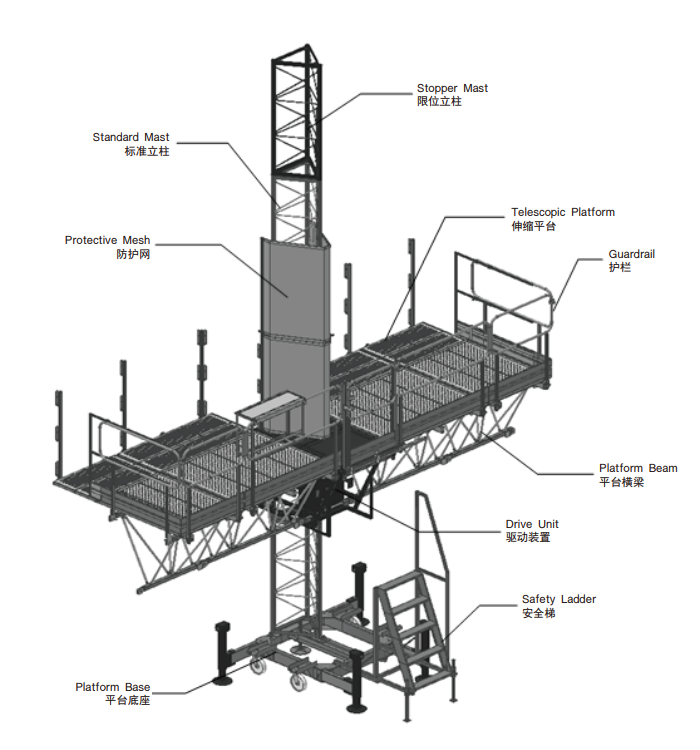

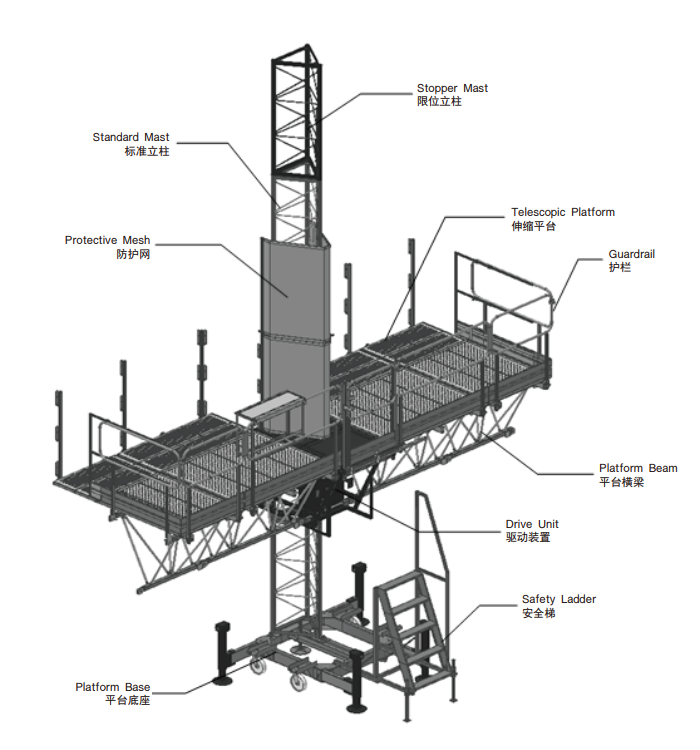

Main Parts of the Platform

The MCWP includes:

- Mast modules are made of strong galvanized steel.

- Drive unit with two motors

- Wide platform that can extend up to 3 meters

- Mobile base with wheels

- Wall brackets to keep the mast stable.

Each part is designed for long service life and high safety.

Why the MCWP Is Better Than Traditional Scaffolding

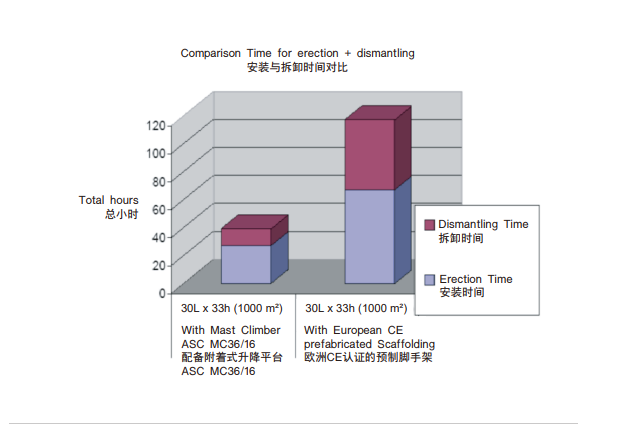

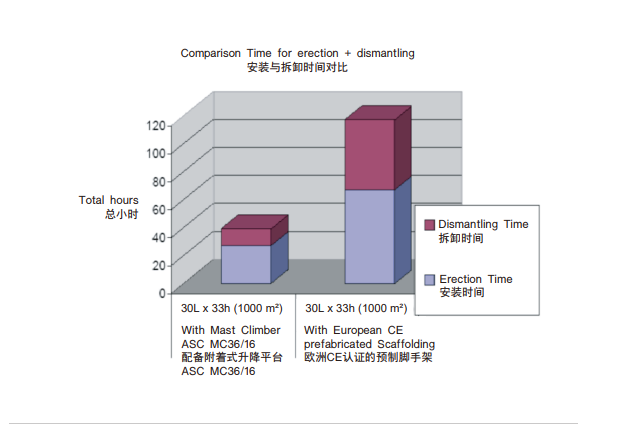

1. Much Faster to Install

A large 30m × 30m platform can be installed by only two people in one day, while traditional scaffolding erection on the same footprint could take a full workweek. This means MCWPs are 10 times faster than scaffolding, making significant time savings in your project schedule.

2. Saves Money and Steel

For a 1,000 m² façade:

Traditional scaffolding: 22 tons of steel

MCWP: 5 tons

This saves up to 80% of materials.

3. Safer for Workers

With stable lifting, anti-fall devices, and clear controls, the MCWP makes high-altitude work much safer.

4. More Comfortable and Efficient

Workers stand on a wide and steady platform, not on narrow pipes. This reduces fatigue and makes work easier.

5. Less Dependence on Crane

MCWP supports horizontal loading, reducing the need for tower cranes.

6. Supports Parallel Work

The façade team can work on lower floors while the main structure continues on upper floors, helping shorten the entire project schedule. By facilitating such parallel work, the MCWP effectively cuts the critical path by three weeks in a typical high-rise building timeline, providing a significant advantage for construction planners.

Where the MCWP Is Used

The Electric MCWP is flexible and fits many types of construction projects:

✔ New Buildings

- Curtain walls

- Brickwork

- Painting and plastering

- Window installation

✔ Special Structures

- Chimneys

- Water towers

- Buildings with curves or special shapes

- Inclined or circular structures

- Ultra-high dams

✔ Renovation Projects

- Old façade upgrades

- Insulation projects

- Window replacement

- Repair and painting

✔ Industrial Work

- Shipbuilding

- Airplane maintenance

- Power plants

- Chemical plants

- Bridges

The MCWP is used on commercial, residential, government, and industrial buildings.

Project Examples

The MCWP has already been used in many important projects, such as Beijing Fangzhuang residential renovation.

The Beijing Fangzhuang Residential Renovation Project is one of the best examples of the Electric Mast Climbing Work Platform in real use. Fangzhuang is one of Beijing’s older residential communities, and many of its buildings needed exterior repairs, insulation upgrades, and safety improvements. Traditional scaffolding would have been slow, costly, and disruptive to the residents living inside the buildings.

To solve these problems, the project team chose the Electric MCWP as the main working platform for the entire renovation.

Why was the MCWP needed?

The Fangzhuang buildings had several challenges:

- The façades were old and needed energy-saving insulation work

- Many balconies and windows required repairs

- The community remained fully occupied, so safety and noise control were crucial

- The building layout was irregular, making traditional scaffolding challenging to install

The MCWP provided a simple and safe solution that fit all these needs.

How the MCWP Helped the Project

The Electric Mast Climbing Work Platform brought several major advantages:

1. Faster Renovation with Less Disruption

The MCWP moved smoothly along the building, allowing workers to reach any height easily.

This helped the team finish work much faster than using scaffolding. Faster work meant less disturbance for residents.

2. Safer Work for Both Workers and Residents

With its strong safety systems—such as anti-fall devices, limit switches, and auto-leveling—the MCWP gave workers a safe platform for repairs.

Because the system used fewer loose materials than scaffolding, the surrounding area became much safer for people walking below.

3. Perfect for Insulation and Façade Repair

The wide platform gave workers more room to install insulation boards, replace broken tiles, repair cracks, and paint the exterior walls.

This made the building look new while improving its energy efficiency.

4. Easy to Use on Complex Building Shapes

Some Fangzhuang buildings had balconies and recessed irregular corners.

Using traditional scaffolding would have been complicated and time-consuming. But the MCWP’s adjustable platform made it easy to fit different building shapes.

Project Results

Thanks to the Electric MCWP:

- The renovation was completed faster than the original schedule

- The overall cost was reduced because less steel and labor were needed

- Residents experienced minimal noise and daily disruption

- The building became more energy-efficient and visually improved

- All work was carried out with a strong focus on safety

The Fangzhuang renovation is now considered one of the model cases of using MCWPs in old residential community upgrades in Beijing.

Conclusion

The Electric Mast Climbing Work Platform is changing the way the construction industry works. It helps teams build faster, safer, and at a lower cost. It uses less material, reduces labor requirements, and provides a stable working environment for workers in high-rise buildings.

As building standards rise and safety becomes more important, this platform will continue to play a key role in the future of construction.

If you would like to learn more or discuss how MCWPs can support your next project, please don’t hesitate to

contact us. To make it even easier for you, we offer a rapid feasibility study to assess your project’s needs and how an MCWP can provide benefits. Reach out to schedule your feasibility study, and let us help you take the first step in optimizing your construction process.