What Is Aluminium Formwork and Why Is It Gaining Popularity in Modern Construction?

How Aluminium Formwork Differs from Traditional Formwork Materials

Aluminium formwork systems differ from classic wood and iron options because of their light weight, sturdiness, and strong building accuracy. Aluminum formwork serves as a fresh type of building mold after wood and steel versions. It uses aluminum alloy shapes as the key material. Workers make these molds through machine work, joining, and other steps. They suit concrete jobs well. Wood molds often twist and wear out over time. Iron ones weigh more and can rust easily. But aluminium provides a rust-proof choice that you can use again and again. Aluminum formwork weighs little, so it’s simple to move around. This makes setup quick and secure. Such easy handling cuts down on worker effort. It also speeds up tasks at the site. Plus, its exact sizes give a flat concrete surface. That cuts back on smoothing or extra fixes later.

What Are the Core Components of an Aluminium Formwork System?

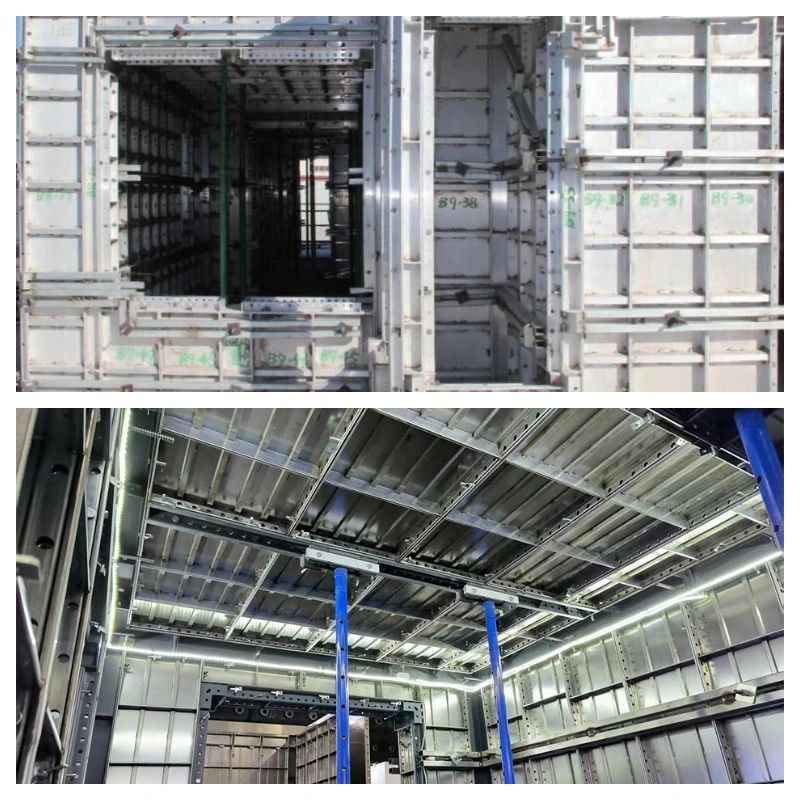

The aluminium formwork system includes a few linked parts. Together, they form the concrete shape. Main building pieces cover wall panels, floor panels, beam bottoms, and support poles. Other items like connecting rods, clips, locks, and edge pieces add to this. They help keep things straight and steady. Teams design each setup to fit the job’s exact needs. So, it works well for various building tasks. All parts match up tightly with little cutting or tweaking on-site. This boosts setup pace and cuts down on wasted supplies.

Which Types of Projects Benefit Most from Aluminium Formwork?

Jobs with repeated patterns and short deadlines gain the most from aluminium formwork. This leads to big savings in costs for builds with similar designs. Think low-cost homes or packed urban areas. Tall apartment towers often use this method. It keeps things even across many levels. Group home Projects also profit from the quick finish per level that aluminium setups allow. Business buildings that need to reuse forms often value aluminium’s tough build and repeated use. Each set can handle up to 300 rounds.

What Are the Different Types of Aluminium Formwork Systems Available Today?

Modular Aluminium Panel Systems for Standardized Construction Needs

Modular aluminium formwork systems fit big jobs with even design rules. These ready-made panels come in set sizes. Workers put them together with basic training. Aluminum formwork systems speed up build schedules a lot. They let teams finish one level in just seven days. Their simple connect style suits builders who want to grow their work without losing quality.

Customizable Aluminium Formwork Systems for Complex Designs

For building plans with bends, odd walls, or special parts, customizable aluminium formwork gives the needed bend. Teams create these using drawing software to match plans exactly. GOWE uses careful design and makes-to-order building from site drawings. They also test fit in the factory. This cuts all likely issues before shipping to the job site. As a result, it boosts build speed and exactness greatly. Custom setups matter when shape accuracy counts most. For example, in blended business or public buildings.

Hybrid Aluminium Formwork Systems Integrating Other Materials

Hybrid systems mix aluminium with items like wood sheets or plastic in spots that don’t hold weight. This balances price and works well. Such setups help where money limits exist. But you still need some repeat use and accuracy. Aluminium goes where toughness matters. You swap in other stuff elsewhere. So, builders lower total costs. Yet they keep the key strength safe.

How to Evaluate the Advantages and Limitations of Aluminium Formwork?

Technical Advantages That Improve Construction Efficiency

Aluminium formwork brings solid tech perks that smooth out job flow. The setup lets you pour walls and floors in one go. This ramps up build speed. It also creates a firm, single-piece build with a fine concrete look. Its light build aids hand moving and a no-crane setup. That trims machine expenses. Built for lasting use, aluminum formwork panels work up to 300 times. Quality stays solid. The setup’s exactness also aids smooth ties with mechanical, electrical, and plumbing (MEP) parts.

Common Challenges Faced When Using Aluminium Formwork Systems

Aluminium formwork has upsides, but it comes with some hurdles. The starting price runs much higher than basic stuff like wood sheets or logs. Also, since parts come pre-made from detailed plans, changes after making prove hard to handle. So, good planning in early design stages matters. It avoids pricey fixes down the line. On top of that, the setup shows little flex once built.

Economic Considerations in Choosing Aluminium Over Other Materials

The first outlay for aluminium formwork pays off through ongoing cuts in worker pay and quicker job ends. The system skips wood or sheets. This trims supply costs and scraps. Also, its rust resistance and power keep upkeep low over many repeat uses. For builders running dense or time-tight jobs, aluminium formwork often wins on money in the long run.

How Can Contractors Choose the Right Aluminium Formwork System Based on Project Needs?

Key Factors to Consider Before Selecting a System Type

Picking the right aluminium formwork system relies on job details like size, layout trickiness, level repeats, money limits, and time frame. Contractors should check if their team knows aluminium setups. Or if training needs to happen.

Design Optimization Strategies for Efficient Use of Aluminium Formwork

Smart use starts with early team-up between designers, structure experts, and form makers. Using BIM (Building Information Modeling) tools lets you test the put-together steps. It spots issues before making. The tight fits of cut aluminum parts keep their shape and surface steady level by level.

Installation Best Practices That Maximize System Performance

Planning Phase Essentials

Right site checks and full layout sketches form the base before ordering aluminium formwork parts. Mistakes here can cause expensive waits or wrong fits.

Assembly Phase Guidelines

Sticking to the maker’s order keeps building strength and makes the workflow smooth. Set up each panel according to the marked guides.

Maintenance & Handling Recommendations

To stretch the system’s life—up to 250–300 uses—clean panels after every job. Store them in dry spots. Swap out any hurt parts right away. This holds size accuracy.

How GOWE’s Aluminium Formwork Solutions Address Real Contractor Challenges?

Our Approach to Designing Reliable and Efficient Systems for Every Project Type

At GOWE, we supply both modular and made-to-fit aluminium formwork systems. We shape them to each job’s build plan. GOWE aluminum formwork system is composed of several independent systems, such as Wall formwork, Top formwork, and Prop. Our engineering team works closely with builders from plan start to setup end. This ensures full match with the design and MEP plans.

What Makes GOWE’s Aluminium Formwork Stand Out Technically?

Precision Engineering

We use CNC machine work that hits size fits within ±0.1mm. So, every part joins smoothly on site.

Durability & Reusability

With high-strength and lightweight, GOWE aluminium formwork is an ideal choice for construction, and highly acclaimed by construction workers due to its light weight and flexibility. Our systems use 6061-T6 grade aluminium alloy that withstands up to 60kN/m² of concrete pressure and can be reused up to 300 times under proper maintenance.

Easy Assembly System

Our patented locking mechanism reduces panel assembly time by more than 30% compared to standard solutions. The intuitive labeling allows even semi-skilled workers to erect systems with minimal supervision.

How We Help Contractors Reduce Costs While Improving Build Quality

Speed of Execution

Our aluminium formwork systems reduce slab cycle times from an average of 10 days down to just 4–5 days per floor—making them ideal for fast-track projects.

Reduced Labor Dependency

Minimal training is required due to our color-coded panels and component labeling strategy, which simplifies on-site logistics.

Logistics & Support

GOWE provides comprehensive support, including technical onsite guidance during initial installations as well as global logistics coordination for timely delivery.

FAQ

Q: What is aluminium formwork used for in construction?

A: Aluminium formwork is primarily used for casting concrete structures such as walls, slabs, columns, beams, staircases, and balconies in residential or commercial buildings. It enables faster construction cycles by allowing simultaneous pouring of vertical and horizontal elements.

Q: How does aluminium formwork compare with traditional plywood formwork?

A: Aluminium formwork offers higher precision, durability (up to 300 reuses), better surface finish, and quicker assembly than plywood systems, which degrade quickly and require more frequent replacement.

Q: Which factors should I consider when selecting an aluminium formwork system?

A: Consider project scale, floor plan repetition, timeline requirements, budget constraints, site access conditions, and workforce familiarity with aluminium systems before making a choice.

Q: Can aluminium formwork be reused on multiple projects?

A: Yes. High-quality systems like GOWE’s can be reused up to 300 times when maintained properly, making them cost-effective for developers handling repetitive or multi-phase projects.

Q: What are the top benefits of using aluminium formwork in high-rise construction?

A: Key benefits include faster floor cycles (as low as 4–5 days), reduced labor dependency, high concrete finish quality requiring no plastering, dimensional consistency across floors, and long-term cost efficiency due to reusability.