Because both scaffolding and formwork involve building temporary buildings, this is a recurring question in construction. But they have very different uses:

Scaffolding: A temporary platform that workers use to stand on as they build, fix, or finish a building. It gives people access, freedom of movement, and safety.

Formwork is a temporary mold device that holds concrete in place and shapes it until it hardens.

To put it simply, scaffolding is for workers and formwork is for concrete.

What is another name for formwork?

People may call formwork:

Falsework (temporary support structures)

Molds or Molding Systems

Temporary Works (generic construction support systems)

There are differences between each phrase, but “formwork” is still the most widely used term in current construction engineering.

Is Formwork Only for Shaping Concrete?

Yes, mostly. The main job of formwork is to keep new concrete in place until it cures. But it does more than just shape:

Makes sure that the structure is in line.

Gives the surface a polish (smooth, ribbed, or patterned).

Keeps things protected while they are curing.

In some advanced projects, permanent formwork systems are used. This means that the formwork itself becomes part of the building (like precast panels in tunnels).

How long should shuttering stay up?

The length of time depends on the kind of member, the span, the load, and the curing circumstances.

General Rules (Based on IS Codes and ACI Standards):

1–2 days for walls, columns, and other vertical structures

7 days for slabs (up to 5 m span)

Slabs (more than 5 m span): 10 days

14 days for beams and arches (up to 6 m span)

21 days for beams and arches with a span of more than 6 m

Note: Taking off the shuttering too soon can cause cracking, bending, or falling down.

How Do They Make Formwork?

The type of structure, the cost, and the requirement to reuse the formwork all affect its design.

1. Formwork for Timber

Pros: It’s cheap, easy to cut, and can be shaped in many ways.

Disadvantages: It bends quickly, soaks up water, and can only be used a few times.

2. Steel Formwork

Pros: Strong, may be used again, and gives a smooth finish.

Cons: It’s heavy, expensive, and needs trained workers.

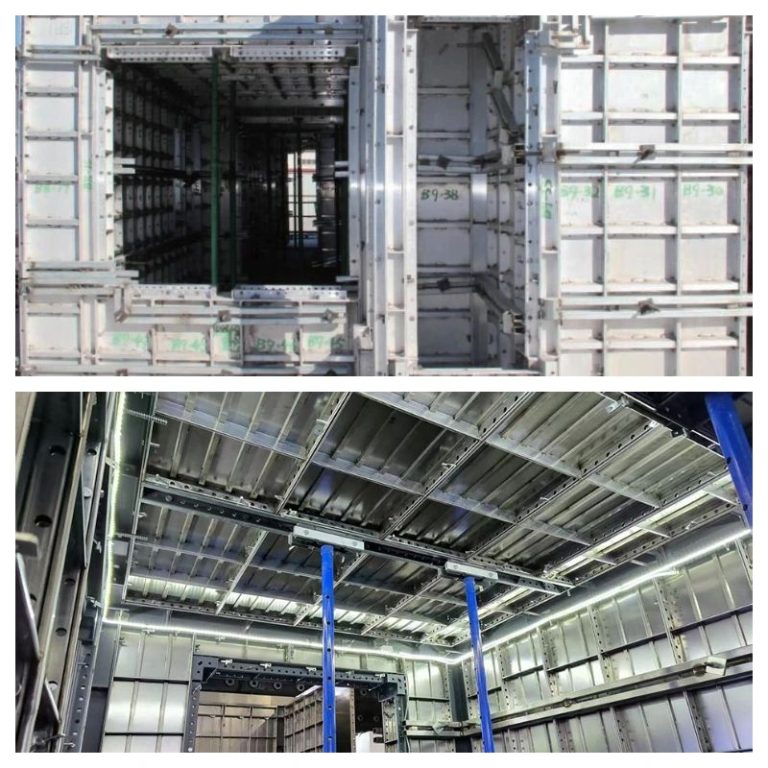

3. Aluminum Formwork

Pros: It’s light, simple to move, and used a lot in high-rise buildings.

Cons: It’s expensive and there aren’t many options for changing it.

4. Plastic Formwork

Pros: inexpensive, light, and suitable for small jobs.

Cons: Not as strong, not good for high loads.

What is the Point of Shuttering?

Shuttering makes sure that:

Structural parts must be the right shape and size.

Stopping cement paste from leaking.

The surface finish is smooth and doesn’t have any honeycombing.

Support that can hold weight till the concrete hardens.

What Do You Call a Moving Formwork?

The name for a moving formwork is:

Slip Form is a type of formwork that moves all the time and is used to build towering structures like chimneys, silos, and high-rise skyscrapers.

Jump Form: Moves up in phases to build the cores and towers of high-rise buildings.

People like these methods in modern building since they save time and work.

What does a good formwork need to do?

A good formwork must:

Be sturdy enough to handle the pressure of wet concrete.

Be light but strong so that you can easily handle it.

To keep the cement slurry from leaking out, it must be leak-proof.

Make it easy to take off without hurting the concrete.

Be able to be used again to save money.

Make sure workers are safe when they put it up and take it down.

How Long Before Stripping the Formwork?

The strength of the concrete affects how long it takes to strip the formwork. In general:

Before being taken away, concrete should have at least 70% of its compressive strength.

In hot areas, stripping might happen sooner, while in cold climates, it takes longer for the curing process to work.

How Many Shuttering Are in Concrete?

To figure out how much shuttering is needed, you need to know how many square meters (m²) of the surface area are in touch with fresh concrete.

Formula:

Shuttering Area = Height × Perimeter of member (for walls and columns)

It has the top, bottom, and sides for slabs and beams.

For example:

A column that is 3m tall and has a cross-section of 0.3m by 0.3m

= 3m × (0.3 + 0.3 + 0.3 + 0.3) equals 3.6 m² of shuttering.

Is formwork a temporary job?

Yes. Formwork is a type of temporary building work that is meant to be taken down after the concrete has set. Some projects, on the other hand, use permanent formwork, including precast panels that stay in place.

What does a formwork job mean?

What you do in a formwork job is:

Making, cutting, and putting together formwork.

Putting up shuttering and centering.

Making sure everything is in line and safe.

Taking off and keeping reusable panels.

People who are good at this are typically termed formwork carpenters or shuttering carpenters.

Using Formwork and Shuttering the Right Way

1. Things to think about for safety

Make sure to use the right scaffolding and supports.

Check materials for cracks or other problems.

Teach workers how to safely install and strip.

2. Tips for Saving Money

If you can, utilize steel or aluminum panels again.

Use less wood to cut down on waste.

Choose modular formwork systems.

3. Reuse and sustainability

You can utilize steel and aluminum formwork more than 100 times.

If you take care of it, you can use wood and plywood 5 to 10 times.

Using eco-friendly options like plastic formwork is better for the environment.

Many construction companies now rely on GOWE’s sustainable formwork systems, which are designed for maximum reusability and minimal waste, making projects both cost-efficient and environmentally friendly.

Case Studies: Actual Instances of Formwork and Shuttering

1. Building with many floors

Aluminum formwork is a popular choice for building high-rises since it is light and can be used again. It speeds up building and cuts down on labor.

2. Building Bridges

Steel formwork is the best choice for bridges since it is strong and can handle long spans. Slip-form methods are also common for pouring concrete continuously.

3. Projects for Homes

For tiny homes, timber and plywood shutters are widespread since they are cheaper and easier to deal with, especially in rural locations. A recent project by GOWE used lightweight aluminum shuttering panels for affordable housing developments. This reduced construction time by nearly 30% compared to traditional methods, showing how modern systems can make residential projects more efficient.

Commonly Asked Questions (FAQs)

1. Are shuttering and centering the same thing?

No. Shuttering is used for vertical buildings like walls and columns, whereas centering is used for horizontal structures like slabs and beams.

2. Can you utilize formwork again?

Yes. Depending on how well they are taken care of, steel and aluminum formwork can be used again 50 to 200 times. Wood is not as reusable.

3. What kinds of materials are utilized to make formwork?

Wood, plywood, steel, aluminum, and plastic are the most prevalent materials.

4. How much more does it cost to use shuttering instead of formwork?

Costs differ by material because shuttering is part of formwork. Steel costs a lot but lasts a long time. Wood is cheaper but can’t be used again.

5. Is it better to use steel or wood for formwork?

Steel is ideal for big jobs since it is strong and can be used again. For tiny, cheap projects, wood is the best choice.

6. What happens if you take down the shutter too soon?

It can cause cracks, collapse, or a bad surface finish, which could make the structure unsafe.

Final Thoughts

So, is shuttering and formwork the same thing?

Formwork is the whole system of temporary molds, supports, and braces that are utilized to build with concrete.

Shuttering is a part of formwork. It is the panels or molds that shape concrete directly.

Both are necessary for building to be strong, safe, and accurate. The proper sort of material, whether it’s wood, steel, aluminum, or plastic, depends on the size of the project, the budget, and how likely it is to be used again.

If you’re looking for reliable and cost-effective construction solutions, GOWE provides high-quality formwork and shuttering systems designed to save time and money while ensuring maximum safety.