Why is Aluminium Formwork a Game-Changer in Modern Construction Projects?

What Makes Aluminium Formwork Different from Traditional Systems?

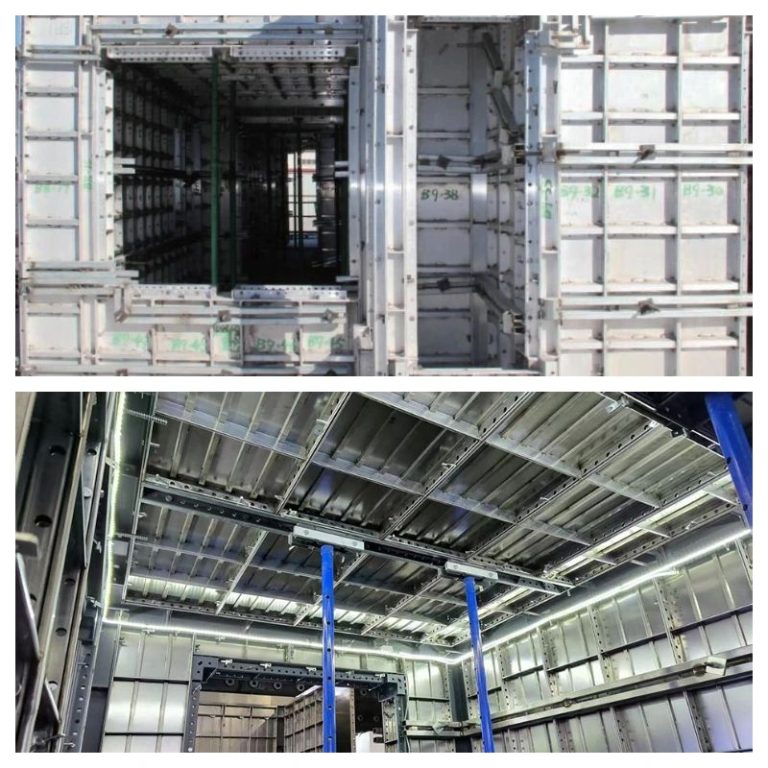

Aluminium formwork provides a bold shift from timber and steel formwork. It blends strong build, light weight, and exact crafting. This formwork uses aluminum alloy profiles as its main material. It is shaped through machining and welding into templates fit for concrete projects. Unlike older systems that need heavy labor and give uneven results, aluminium setups are pre-built for precision and consistency. This leads to a better lineup of parts like walls, beams, and columns. It also boosts safety on-site.

How Does the Lightweight Nature of Aluminium Improve Efficiency?

The lightweight aluminium formwork greatly lifts building speed. It makes handling simple and cuts the need for big machines. This formwork is easy to move and set up. Workers can put it together without cranes or heavy gear. Even less skilled workers can learn to use it well. This speeds up setup and lowers worker tiredness. It suits both skilled and new teams. This piece fits many building sites and worker skill levels.

In What Ways Does Reusability Contribute to Long-Term Cost Savings?

One key perk of aluminium formwork is its great reuse potential. Built for long use, aluminum formwork panels can be used up to 200 times without losing quality. Yet, top systems like those from GOWE last for 250–300 cycles. This sharply cuts the need for new materials for many projects. By skipping timber or plywood, builders save on repeat costs. It also helps the planet by cutting waste.

How Does Aluminium Formwork Accelerate Project Timelines Without Compromising Quality?

What Role Does Precision Engineering Play in Faster Construction?

Precision crafting in aluminium formwork ensures steady sizes across all building parts. The machined aluminum pieces keep exact shapes and surface quality from floor to floor. This precision stops delays from bad lineup or rework, often seen with older methods. It also blends well with pre-made plumbing and electrical parts. This allows a smoother workflow between trades.

How Does Early Strength Gain of Concrete Complement Aluminium Formwork?

Aluminum formwork supports quick form removal. It works well with fast-setting concrete mixes. It can handle 60KN/m² concrete side pressure. It allows one-time full pouring and shaping of vertical and horizontal parts. Plus, it can be taken apart early for horizontal parts. This means slabs can be removed sooner without harming the strength. It frees resources for use on higher floors. As a result, floor cycle times drop a lot.

Can Streamlined Assembly Reduce Labour Dependence and Delays?

Yes, simple assembly plays a big role in cutting labor needs while keeping high output. Workers can set it up without cranes or heavy gear. Even less skilled workers can learn to build it well. The modular design makes setup fast by locking parts together on-site. The aluminum formwork system casts walls and slabs in one go. This greatly speeds up building while giving a strong, solid structure with a top concrete finish.

What Are the Key Cost Benefits of Using Aluminium Formwork in Large-Scale Projects?

How Do Reduced Labour Costs Impact Overall Budgeting?

Lower labor costs directly shape project budgets by cutting man-hours needed per square meter built. Aluminium formwork is simple to put together, even for less skilled workers. This saves on hiring special teams or renting cranes. It is light and easy to handle. Less skilled workers can learn to set it up well. In big projects where labor is a major cost, these savings grow large.

In What Ways Do Minimal Material Wastage and Site Cleanliness Save Money?

Aluminium systems make little waste compared to timber setups that need cutting or tweaking on-site. This system skips timber or plywood, lowering material costs and waste. Also, cleaner sites cut cleaning costs and lower accident risks. This adds to savings through better safety records.

How Does Faster Project Turnover Improve Financial Returns?

Quicker turnover lets builders finish projects early or within tight deadlines. This allows faster move-in or sales. Aluminum formwork systems speed up building time, saving up to 50% of total construction time. Faster finishes mean earlier income from rent or sales. It also cuts interest on borrowed funds.

Where Does Aluminium Formwork Deliver the Greatest Value Across Building Types?

Is It Suitable for High-Rise Residential and Commercial Developments?

Yes, aluminium formwork shines in high-rise buildings. It keeps steady structural precision across many floors. The aluminum formwork system fits various building designs, from low-rise to high-rise. It works well with scaffolding systems. This boosts worker safety at height while keeping fast build cycles key in city projects.

How Does It Perform in Repetitive Layouts Like Apartments or Hotels?

Repeated floor plans in apartments or hotels gain a lot from reusable aluminium panels made during the first setup. This leads to big cost savings for projects with repeated layouts, like low-cost housing or dense builds. Once a unit type is set at the factory level, as done by GOWE, the same setup can be quickly copied across all floors without changes.

Can It Be Effectively Used in Infrastructure Projects with Tight Schedules?

Absolutely. Projects like parking structures or transit stations often face strict deadlines where delays cost extra. GOWE uses careful design and custom production based on building plans. This cuts problems before the formwork reaches the site. The pre-made approach and fast cycle times make aluminium formwork a great fix when time is tight.

Why Choose GOWE for High-Performance Aluminium Formwork Solutions?

Who Are We and What Sets GOWE Apart in the Formwork Industry?

We are GOWE, a top leader in aluminium formwork technology. We hold over 460 patents worldwide. Our team has more than 500 experts in quality control (QC), quality assurance (QA), and R&D design engineering. They ensure every product meets global standards before reaching your site.

What Features Define Our Aluminium Formwork Systems?

High Durability with 250–300 Reuses

Our panels are built for long life. They offer 250–300 reuse cycles without losing structural strength or surface quality.

Modular Design for Rapid Assembly and Disassembly

The GOWE aluminum formwork system includes separate parts like Wall formwork, Top formwork, and Prop. This makes building quick and easy.

Smooth Concrete Finish Eliminating Plastering Needs

The smooth concrete finish skips the need for plastering. This saves time and finishing costs a lot.

Integrated Safety Features for On-Site Efficiency

Our systems blend well with scaffolding solutions. They suit high-rise work, boosting output and worker safety at the same time.

How Do We Support Our Clients Throughout the Project Lifecycle?

From first design talks based on your building plans to trial setups at our factory, we give full support. This ensures a few issues during site work. Careful design and custom production based on building plans greatly boost building speed and precision.

FAQ

Q: What are the key benefits of using aluminium formwork over traditional timber systems?

A: Aluminium formwork gives faster setup times due to its light build. It offers top surface finishes that skip plastering needs. It can be reused up to 250–300 times. This cuts long-term costs a lot compared to timber options.

Q: Which brand offers reliable aluminium formworks with high reuse potential?

A: GOWE provides aluminium formworks built for 250–300 reuse cycles. They include built-in safety features and are backed by over 460 patents worldwide.

Q: How do I choose an effective aluminium formwork system?

A: Look for modular design and fit with scaffolding systems for high-rise work. Seek smooth concrete finishes that cut post-casting work. Ensure it comes from a maker offering full project support, like GOWE.

Q: Is aluminium formwork better than plastic modular systems?

A: Plastic may work for small DIY tasks. But aluminium beats it in strength (60kN/m² side pressure hold), reuse (up to 300 times), and precision crafting. It suits big commercial projects better.

Q: Who are the top companies providing advanced aluminium formworks?

A: Top providers like GOWE stand out with heavy R&D work (over 460 patents). They have strong QC/QA teams with over 500 experts, ensuring top product reliability worldwide.