What Is the Right Formwork Material for Your Construction Project? Key Factors to Consider

How Project Scale and Design Complexity Influence Formwork Material Choice

Choosing the appropriate formwork material is directly influenced by the scale of the project and the complexity of its design. For large-scale construction, materials such as steel or aluminum are preferred due to their durability and high reuse potential. Steel formwork, in particular, is known for its strength and dimensional accuracy, making it well-suited for projects that require consistent structural performance over multiple uses.

On the other hand, intricate architectural features or custom geometries benefit greatly from wood formwork. Wood can be easily cut and shaped on-site, providing flexibility that is crucial for achieving complex curves and detailed finishes. However, budget constraints and labor availability must also be factored in. For instance, while steel and aluminum offer long-term savings through reusability, they demand a higher initial investment and skilled handling, which may not align with limited budgets or tight timelines.

How Climate and Environmental Conditions Affect Formwork Performance

Weather points play a big role in picking which formwork item fits the job spot. Steel formwork stays strong. But it is weak to rust in sea or wet areas without proper care. Steel may corrode in humid or coastal environments without proper treatment. This can hurt safety and looks.

Wood is a natural item. It pulls wet easily. This leads to bending or rotting. Wood can warp or degrade in wet conditions unless properly sealed. And it needs to be guarded from bugs like termites.

Aluminum hits a balance by giving its own rust fight. This makes it fit for outside and sea use. Aluminum offers corrosion resistance, but it may react with certain concrete mixes. This needs careful fit checks before use.

Why Choose Wood Formwork? Advantages and Limitations Explained

What Makes Wood a Flexible Option for Formwork Applications?

Wood remains a common pick for formwork in jobs where customization and change matter. The main gain lies in working easily. Wood saws, nails, and changes to meet odd or special build shapes. This makes it the best pick for building parts that need exact detail.

Plus, wood is easy to find and known for building teams worldwide. This cuts train costs and reduces mistakes in joining. It works well for short-term or one-use jobs where reuse is not a big worry. For small home builds or art concrete forms, wood gives a bend and costs less without the need for heavy systems.

What Are the Drawbacks of Using Wood as a Formwork Material?

Wood formwork has clear limits that stop its use in big or long jobs. One key problem is the low reuse chance. Again, wet, push, and wear hurt woodwork much. This raises full costs in jobs that need many concrete fills.

Plus, wood feels the weather more. Open to wet harm, shape change, and termite hit, wood formwork often needs guard care that adds fix work.

Last, get the size truth with wood needs skill in woodwork. Requires skilled carpentry for precise assembly. This makes work quality key to a good end.

How Does Steel Formwork Compare in Strength and Reusability?

What Are the Benefits of Steel Formwork in Structural Applications?

Steel formwork stands as the top answer for high buildings, bridges, and bases that need strong support systems. High load hold power fits heavy build wants. This makes sure steel holds a big concrete push safe without shape change.

Plus, steel gives great size truth. This ensures smooth concrete ends. It cuts surface fix work after take off. High strength allows for repeated use in many jobs. It can be reused many times. This cuts waste in long jobs. This makes it a good pick when cared for correctly.

What Are the Practical Challenges When Using Steel Formwork?

Steel gains come with a high start cost. Higher initial cost compared to wood or aluminum options can push job budgets. This hits small builds.

Handle steel needs machines and know how to work. Heavier weight requires lifting equipment and skilled labor for installation. Plus, it is prone to rust if no good coat is applied, which often needs to be applied. Prone to rust if not properly maintained or coated. Bad care of steel formwork can hurt safety and look over time.

Is Aluminum the Ideal Balance Between Strength and Weight in Formwork?

What Advantages Does Aluminum Offer Over Wood and Steel Formworks?

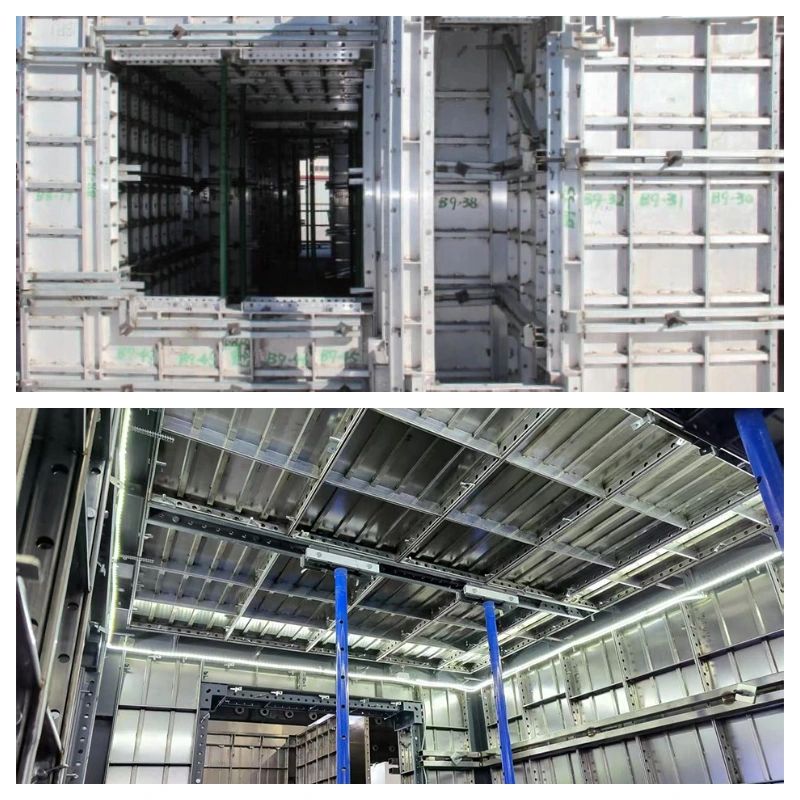

Aluminum formwork sees more as a balance between wood, bend, and steel power. It joins mid-strength with an easy handle from lightweight materials. Lightweight yet strong. This cuts work costs and crane needs. Aluminum cuts heavy lift gear on site.

Rust fight makes it fit for outside or sea spots. Corrosion-resistant properties are ideal for outdoor or marine environments. In run good, part aluminum systems let fast set and break. Modular systems allow quick assembly and disassembly.

Plus, with high-strength and lightweight, GOWE Aluminum formwork is an ideal choice for construction. Workers praise for easy use and good work in up and side fill jobs.

What Limitations Should Be Considered When Selecting Aluminum Formwork?

Aluminum has many gains. But it brings limits. Higher upfront cost than wood, though often less than steel over time, means a money plan is needed when picking an item.

Another hard chemical meets with fresh concrete mixes. It can react with wet concrete unless properly treated or coated. Plus, fit for most normal uses, aluminum may not be the best for very high load cases. Less suitable for extremely high-load applications compared to steel.

Why GOWE Scaffolding Systems Stand Out in the Formwork Industry

Who Are We at GOWE and Why Do We Focus on Scaffolding Solutions?

At GOWE, we focus on giving trust formwork support systems. They make sure that safe and good work is built in all ways. We specialize in formwork support systems tailored for safe, efficient construction workflows. Our team works to give trust scaffolding that meets field rules.

With many years of building knowledge and world bases in Tianjin, Shandong, Jiangsu, Anhui, and more, our promise is rooted in new ideas and builds truth in each good line.

What Makes GOWE Scaffolding a Preferred Choice Among Professionals?

Precision Engineering for Structural Integrity

Made with high-grade steel, with steady load holding, works in the up position. This makes sure a steady need for hard build spots like high buildings and bridge tops.

Modular Design Supporting Versatile Applications

Our scaffolding changes easily to many formwork sets. This saves set time. With our table formwork system design, repetitive dismantling is eliminated. Units are lifted floor to floor by cranes. It only needs to be lifted from the next floor to the same position on the previous floor using a tower crane with special lifting equipment. This raises job speed a lot.

Corrosion Resistance Extending Product Lifespan

Galvanized ends ensure strength even in hard weather. This results in low maintenance costs and a long life in different weather.

Safety Features Enhancing On-site Efficiency

Join lock ways rise steadily in concrete fill runs. These built guards make sure the crew works in a safe frame for all formwork use steps.

FAQ

Q: How do I choose the right formwork material for my construction project?

A: The choice depends on project size, design complexity, budget constraints, and environmental conditions. Wood is flexible for custom designs but has limited reuse; steel offers strength and longevity; aluminum balances weight with reusability.

Q: What are the advantages of using aluminum over wood or steel in formwork?

A: Aluminum formwork is lightweight yet durable, resists corrosion well in outdoor environments, and allows modular assembly. It’s ideal where labor efficiency and environmental durability are priorities.

Q: Is steel formwork better than wood for commercial buildings?

A: Yes. Steel offers higher load capacity and multiple reuses with precise concrete finishes, making it better suited for commercial-scale or high-rise buildings compared to single-use wooden forms.

Q: Which type of formwork performs best in coastal environments?

A: Aluminum formwork performs best due to its corrosion-resistant properties. Steel may corrode without treatment, while wood can absorb moisture unless sealed properly.

Q: What companies provide reliable aluminum formwork systems?

A: GOWE provides high-strength aluminum formwork systems praised for their lightweight build and ease of use. Our solutions integrate wall forms, top forms, props, and scaffolding—offering complete support across vertical structures.