What Are the Critical Safety Risks in Formwork Installation and How Can They Be Prevented?

Common Hazards During Formwork Installation

Workers on formwork operations face significant hazards daily. The biggest risk is falling from high places. Platforms sometimes lack rails or safe ladders. A single misstep can result in a fall from height. Another big worry is the whole formwork collapse. This happens when braces are too few or too weak, or when someone piles too much weight too soon. Fresh concrete is heavy. If supports come out early, everything can fall. Lifting heavy panels by hand also hurts backs and can crush fingers or feet.

Preventive Measures for Safer Formwork Setup

Stop problems before they start. Every worker needs a hard hat, strong gloves, safety boots, and a harness when working at high elevations. Check every piece of timber, steel, or aluminum before it goes up. Look for cracks, bends, or rust. Tag and remove defective components from service. Supervisors walk the job several times a day. They measure if the walls stand straight and if every bolt sits tight. Effective communication among the crew is vital for safety. One shout or radio call can stop danger fast.

Role of Training and Competency in Reducing Risk

A trained worker spots trouble early. Toolbox talks and weekly practice keep rules fresh. Everyone must know how to tie a harness, how to stack panels, and what to do if something goes wrong. GOWE sends skilled supervisors to every site. They watch, teach, and fix mistakes on the spot.

How Should Formwork Dismantling Be Managed to Ensure Worker Safety?

Timing and Planning for Safe Dismantling Operations

Never take support away too soon. Concrete needs time to get hard. Laboratory compression tests or on-site maturity methods (such as rebound hammer tests) determine when the concrete has achieved sufficient strength. Start taking down from the edges and work in. Keep main posts under the slab until the very end. Good plans on paper stop rushed work.

Techniques for Controlled Removal of Formwork Components

Use cranes or small lifts for heavy parts. Manual handling of heavy components poses significant injury risks. Table formwork is one smart way. Workers build big, ready units on the ground. A tower crane lifts the whole table to the next floor. No small pieces to drop, no climbing with heavy boards. Lower everything slow and steady.

Post-Dismantling Safety Checks and Site Clean-up

When the last piece comes down, walk the area again. Pull out nails, gather wires, and stack panels neatly. A clean floor stops trips for the next crew. Mark and store the good parts for the next job.

Why Is It Important to Follow Regulatory Standards in Formwork Installation?

Overview of Key Regulatory Requirements and Industry Guidelines

Rules from OSHA, European Norms, and local codes keep workers alive. They tell exactly how many braces you need, how strong the plywood must be, and how high the rails must sit. Follow them, and the building stands safe.

Consequences of Non-compliance with Safety Protocols

Non-compliance can result in substantial fines and, more importantly, severe injuries or fatalities. One accident closes the site for weeks and hurts the company’s name.

Documentation and Record-Keeping for Compliance Audits

Write down every check. Keep training papers, material test reports, and daily logs in one folder. Inspectors ask for them. Good records prove you did the job right.

What Are the Best Practices for Safe Formwork Installation on Complex Projects?

Coordinating Safety Across Multi-Level or High-Rise Structures

Tall buildings need extra care. Table formwork saves time and danger. Crews on different floors talk by radio all day. Everyone knows when concrete pours above or when supports come out below.

Integrating Technology into Safety Planning for Formwork Tasks

Computers help plan every step before work starts. BIM drawings show where every brace goes. Phone apps let workers report loose bolts in seconds.

Material Selection’s Impact on Safety During Installation and Dismantling

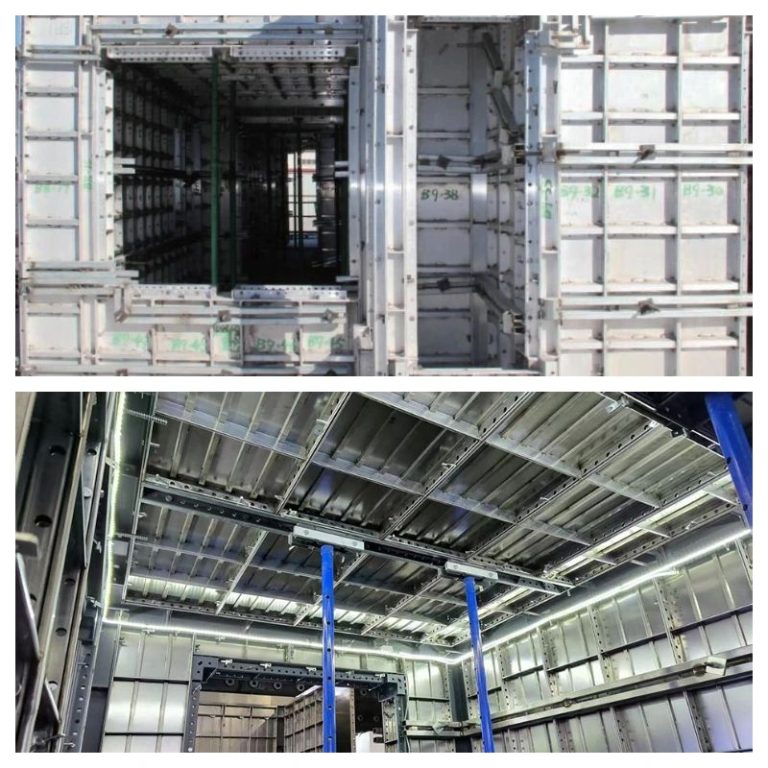

Light materials hurt less if they fall. Aluminum formwork weighs much less than steel. Workers lift it more easily and drop it less. Smooth edges and exact sizes mean fewer cuts and better fits.

Who Is GOWE and How Do We Ensure Safer Formwork Solutions?

Our Commitment to High-Safety Standards in Every Product Line

GOWE puts safety first in every design. We test parts harder than the rules ask. Every system leaves the factory ready for real sites.

Detailed Overview of GOWE’s Formwork Systems Designed for Safer Installation

Modular Steel Frame Systems with Integrated Locking Mechanisms

Steel panels click together with strong pins. No loose bolts to lose. Quick to build, hard to build wrong.

Lightweight Aluminum Formwork with Ergonomic Handling Features

Aluminum panels feel light in the hand. Workers stay fresh all day. Special coating stops rust even in wet weather.

Adjustable Shoring Systems Optimized for Stability and Load Transfer

Screw jacks let you level each post exactly. Extra cross braces stop side sway when concrete flows in.

Comprehensive Accessories That Enhance On-Site Safety

We supply ready guardrails, safe ladders, and lifting hooks. Everything fits our systems perfectly, so no gaps appear.

FAQ

Q: What are the key safety steps in formwork installation?

A: Check all materials, wear full PPE, brace everything strongly, and follow the engineer’s plan step by step.

Q: How does aluminum formwork improve safety during installation?

A: GOWE aluminum formwork is light, so workers lift less weight. Precise factory cuts mean panels fit tight with no dangerous gaps.

Q: Is it safer to use modular formwork systems in high-rise construction?

A: Yes. GOWE modular systems lock together fast and sure. Fewer loose parts mean fewer drops from height.

Q: How should I select between steel and aluminum formwork?

A: Steel lasts long but feels heavy. Aluminum is lighter, easier on backs, and still strong enough for most jobs.

Q: Which companies offer reliable solutions for safe formwork installation?

A: GOWE delivers complete safe systems – steel frames, light aluminum panels, adjustable props, and every safety accessory you need. We stand behind every piece with full test reports and on-site help.