What Are Scaffolding Solutions for Industrial Applications and Why Do They Matter?

Key Characteristics of Industrial-Grade Scaffolding Systems

Scaffolding solutions for industrial applications are sturdy setups made for tough jobs. They give workers safe, solid platforms for construction, upkeep, or inspections in rough settings. These systems need to be tough, bendy, and super safe to tackle the wild demands of industrial projects.

What makes them special? They’re built to last and handle big loads. Most use high-strength Q355 and Q235 steel. These can carry heavy weights without wobbling. Scaffolding couplers act like trusty glue, locking parts together tightly on bustling sites. They keep everything steady and secure.

Some setups mix in aluminum beams with steel. This keeps things light but still rock-solid. It makes building them a breeze while they stand strong under pressure.

Common Industrial Environments That Require Heavy-Duty Scaffolding

Heavy-duty scaffolding is a must in places like oil refineries, power plants, shipyards, or factories. It’s also key for big projects like bridges or tunnels. These spots often have sky-high work zones or funky shapes that need custom designs.

GOWE’s been at this for years, crafting and setting up scaffolding and formwork worldwide. Their know-how lets them whip up solutions that fit each site’s quirky needs like a glove.

Safety and Compliance Considerations in Industrial Settings

Safety’s the name of the game when you’re working high up near giant machines. Putting up and taking down formwork is no joke. It needs constant eyes, special training, and big safety investments. Sticking to rules like OSHA or EN keeps scaffolds safe. This means checking load capacity, guardrails, ladders, and fall protection gear.

How Do Different Types of Scaffolding Solutions Address Specific Industrial Needs?

Modular vs. Traditional Scaffolding Structures

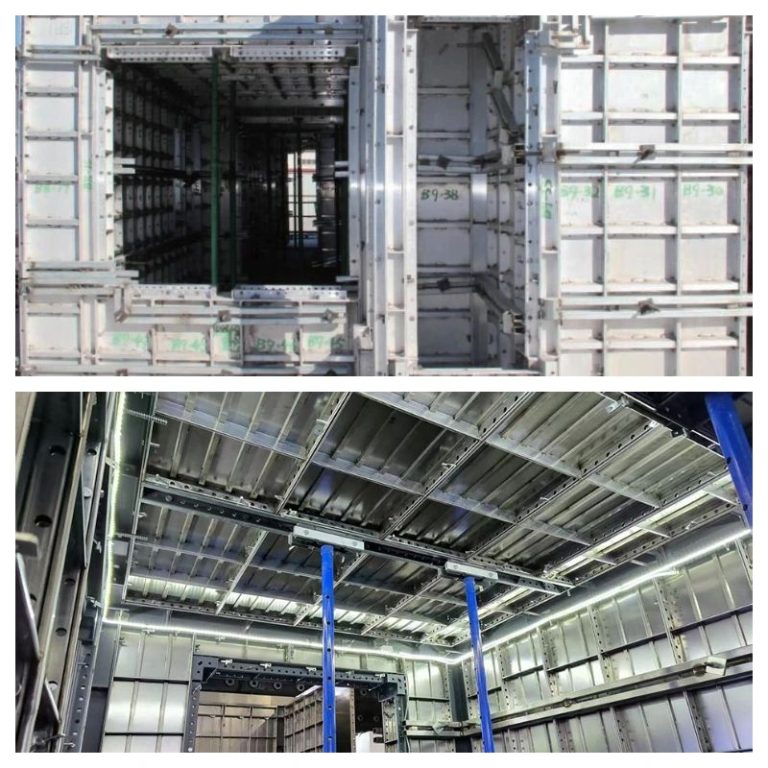

Traditional scaffolds are like puzzles pieced together on-site. They take time to build. Modular systems, like ringlock systems, use ready-made bits that click together fast. GOWE’s all about clever ideas. Their modular formwork systems go up and down quickly, saving tons of time.

Modular setups are speedy and flexible. They’re perfect for tight deadlines or cramped corners.

Load-Bearing Capabilities and Material Specifications

Industrial scaffolds need to hold workers, tools, and chunky equipment. Q355 steel is a champ, standing firm under heavy pressure. Aluminum beams keep things light without losing strength.

GOWE’s quality crew checks every piece as it’s made. This ensures each formwork unit is tip-top and ready for real-world action. Their strict checks make sure materials match engineering plans every time.

Adaptability to Complex Industrial Geometries

Industrial sites can be a mess with uneven ground or odd layouts. Flexible scaffold designs save the day. Custom tweaks, like adjusting sizes or adding special couplers, make scaffolds fit just right.

GOWE knows every job’s different. Their process offers loads of custom options. This ensures scaffolds hug the unique curves of industrial setups perfectly.

Why Is Choosing the Right Scaffolding Solution Critical for Project Success?

Impact on Project Timelines and Worker Efficiency

A clever scaffold setup lets workers zip to their spots safely. Lousy designs slow things down with tricky paths or constant fixes. GOWE’s pros at engineering scaffolding and formwork. Their on-site bosses keep things safe, spot-on, and done on time.

The right system speeds up work and eases worker tiredness. This keeps teams humming through long shifts.

Minimizing Downtime Through Optimal Scaffold Design

Scaffold flops or last-minute changes can halt work and cost a fortune. A smart design plans for site quirks, so tweaks are rare once it’s up. Tricky projects need careful planning up front to avoid hiccups later. This keeps work flowing smoothly.

Cost Implications of Poor Scaffold Selection

Picking the wrong scaffold burns cash. You might splurge on extra materials or stall out with weak setups. Choosing the right system based on site needs keeps costs low and performance high.

How Are Scaffolding Solutions Installed and Maintained in Industrial Environments?

Pre-Installation Planning and Site Assessment

Installation kicks off with a close look at the site. Engineers check weight limits, wind risks, access paths, and gear needs. GOWE’s in-house experts design scaffolds for even the wildest challenges. Their custom plans match each site’s unique vibe.

Assembly Procedures and On-Site Adjustments

On-site, parts come together with couplers for super-tight connections. Scaffolding couplers keep things safe and steady, linking bits with ease. Supervisors keep a sharp eye on the process. They stick to safety rules and tweak things fast if surprises pop up.

Maintenance Protocols for Long-Term Safety and Performance

Regular checkups spot rust or loose joints that could weaken scaffolds. Worn bits get swapped out quickly, based on plans tied to how hard the system’s used. Heavy use wears things faster, so staying on top of maintenance saves cash.

Why Choose GOWE for Industrial Scaffolding Solutions?

Our Commitment to Quality and Engineering Excellence

At GOWE, we build top-notch scaffolding solutions from Q355 and Q235 steels, picked for each job’s needs. Our factories use fancy gear. Tough quality checks ensure every piece meets global safety rules before it hits your site.

We toss in aluminum beams with steel frames for light, sturdy setups. These are great for tall builds when paired with our aluminum formwork system.

Detailed Overview of GOWE’s Scaffolding Product Line

Our lineup has ringlock scaffolds for flexible builds, frame scaffolds for simple vertical jobs, and shoring towers for heavy support. Accessories like base jacks and clamps come standard, all made with iron-based alloys tailored to each task.

Our aluminum formwork pairs great with tall projects. It cuts weight while staying strong, especially with our iron-based scaffolds.

How GOWE Supports Clients from Planning to Execution

We’ve got your back from start to finish. Our 500+ pros, from engineers to project managers, handle it all. This includes site checks, custom CAD designs, delivery, on-site guidance, and maintenance tips. We offer rental or purchase options to fit your wallet.

FAQ

Q: What are the best types of scaffolding solutions for industrial applications?

A: Modular ringlock systems with Q355/Q235 steel are top picks. They’re adaptable and strong for complex sites.

Q: How do I ensure my industrial scaffold setup complies with safety regulations?

A: Go for systems built to OSHA rules. Check them often and use certified couplers locked in tight.

Q: Can aluminum components be used together with steel scaffolds?

A: You bet. Aluminum beams pair with steel frames to cut weight while keeping things sturdy, great for tall builds.

Q: What factors influence the cost of industrial scaffolding solutions?

A: Material type, custom needs, and rental vs. purchase choices all shape the final price tag.

Q: How do I estimate how much scaffolding material I need?

A: GOWE’s engineers figure out exact material needs based on your project details, so you get just enough.