What is the load capacity of a scaffold?

Scaffolding is one of the most important temporary constructions in the building trade. Scaffolds are useful for workers who are painting a high-rise building, fixing bridges or doing regular maintenance. They give workers stability and access. But one of the most important things about scaffolding is how much weight it can hold. If you go above the limit, the results might be terrible, such as collapses, injuries, or even deaths.

The kind, design, materials, and safety regulations of a scaffold all affect how much weight it can hold. It’s important for both contractors and engineers, as well as workers who utilise scaffolds every day, to understand these things. In this post, we’ll talk about the many types of scaffold loads, what affects them, and how to figure out how much weight is safe to put on them. We’ll also talk about some frequent mistakes to avoid.

Getting to Know the Basics of Scaffolding

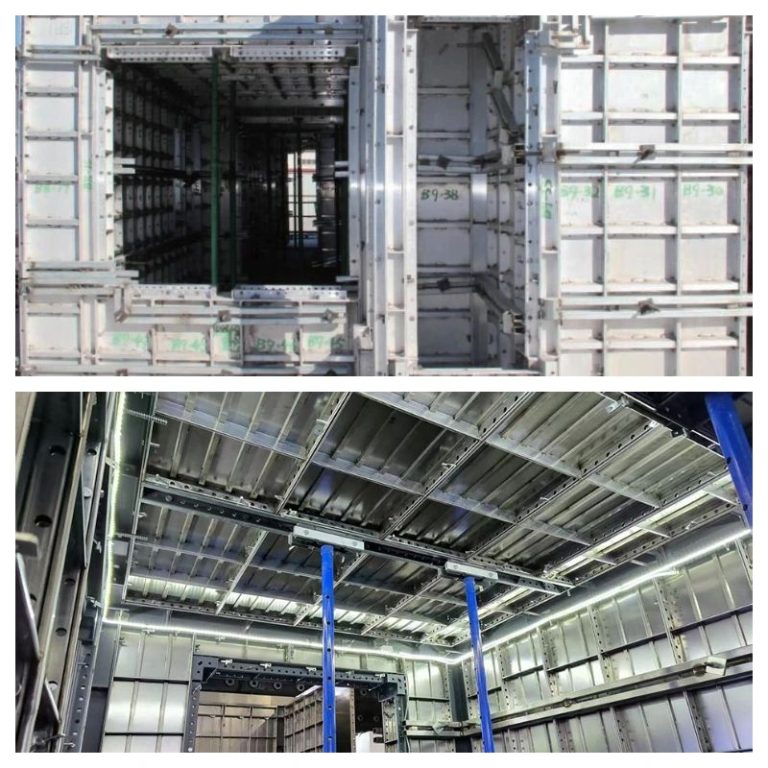

Before you learn about load capacity, you first know the foundations of scaffolds. A scaffold is a temporary raised platform that supports workers, tools, and materials while they work on building or fixing things.

There are different types of scaffolds:

Supported scaffolds are made of frames, poles, or tubes and are built from the ground up.

Suspended scaffolds are platforms that dangle from ropes or cables.

Rolling scaffolds are constructions on wheels that can be moved easily.

The maximum load rating for each type of scaffold is different. That’s why it’s important to know what kind of scaffold system is being utilised before checking its capacity. At GOWE, our product specifications always clearly state the intended use and load class for each system we manufacture.

Types of Scaffold Load Ratings

There are three primary load categories for scaffolds, and each is made for a different job:

Light-Duty Scaffolds

Can hold up to 25 pounds per square foot (psf).

Good for things like cleaning, painting, or light finishing work.

Medium-Duty Scaffolds

Can hold up to 50 pounds per square foot.

Made for general construction labour like plastering, bricklaying, and carrying equipment that aren’t too heavy.

Heavy–Duty Scaffolds

Can hold 75 psf or more.

Needed for jobs that include moving big things like masonry blocks, stonework, or mechanical systems.

Choosing the improper category can often lead to overloading, which is one of the most common reasons for scaffold accidents.

Things That Affect the Maximum Load on a Scaffold

There are many things that affect how much weight a structure can hold:

Strength of the Material: Steel scaffolds can usually hold more weight than aluminium or wood scaffolds.

Standards for Design and Engineering – A scaffold with cross-bracing and foundation plates that is well-made is much more stable.

Height and Width: Taller scaffolds may need extra stabilisers to keep their load capacity.

Load Distribution: It’s safer to have loads spread out evenly than to have them all in one place.

Wind, rain, or uneven ground can make a scaffold less safe than it should be.

If all the weight is on one side of the platform, a scaffold that is made to hold 500 pounds may not be safe.

OSHA and International Safety Standards

There are specific rules that scaffolds must follow to keep people safe.

OSHA stands for the Occupational Safety and Health Administration in the US.

Scaffolds must be able to hold at least four times the maximum load they are meant to hold.

For instance, if the workers and materials weigh 500 lbs, the scaffold must be able to hold 2,000 lbs safely.

European Standards (EN 12811)

Make sure that load-bearing capacities are classified in the same way in all EU nations.

Standards from ISO

Give general rules on how to design, put together, and load scaffolding.

Local construction regulations may have extra rules that must be followed for safety and legal reasons.

How to Figure Out the Most Load Capacity

You need to think about both the living load (people, tools, and materials) and the dead load (the weight of the scaffold itself) when figuring out how much weight it can hold.

To figure it out: Total Load = Dead Load + Live Load

For example:

Weight of the scaffold (dead load) = 500 lbs

People and tools (live load) = 1,000 lbs

The total weight is 1,500 lbs.

For OSHA compliance, the scaffold must be able to hold 6,000 lbs (1,500 times 4).

This calculation makes sure there is a big safety margin, which keeps workers safe from accidents. Always consult the engineering specifications provided by your supplier, like GOWE SCAFFOLDING‘s detailed load charts, for accurate dead load calculations.

Mistakes that happen often when managing scaffold loads

You can stop a lot of scaffold accidents from happening. The most common mistakes are:

Overloading scaffolds is putting too many workers or supplies on them, which makes them too heavy.

Uneven weight distribution is putting bricks or tools on one side instead of spreading them out evenly.

Not following the manufacturer’s instructions:Each scaffold system has its load ratings that must be obeyed.

These flaws can easily make even the strongest scaffold unsafe.

Useful Advice for Using Scaffolding Safely

To make sure that scaffolding is safe, you need to plan ahead and check it often. Here are some good ways to do things:

Check scaffolds every day before using them to make sure they aren’t broken, have loose connections, or have weak platforms.

Choose the right scaffold for the job, whether it’s light, medium, or heavy duty. GOWE SCAFFOLDING offers a full range of products to safely match any project requirement.

Teach workers how to load things safely and why it’s important not to go over the weight limit.

Don’t make temporary changes like adding planks or supports that the manufacturer doesn’t approve of.

Following the same safety rules every time saves lives and keeps things from getting too expensive.

Examples of Scaffolding Failures in Real Life

It’s not uncommon to hear about scaffold collapses in the news. For example:

In New York, a case featured a scaffold that was too heavy with bricks and fell, hurting many people.

In the UK, a scaffold that wasn’t properly balanced and was hauling heavy machinery tipped over, damaging the building and hurting workers.

These events show how important it is to obey safety rules and respect load ratings.

Questions that are often asked (FAQs)

Q1: How much weight can a scaffold hold per square foot?

Light-duty is 25 psf, medium-duty is 50 psf, and heavy-duty is 75 psf or more.

Q2: How can I tell if my scaffold is too heavy?

Some warning indications are when the platform sags, makes creaking sounds, or when parts are clearly bending.

Q3: Are scaffolds strong enough to hold big machinery?

No, scaffolds are not made for machinery like forklifts. You should only put workers and materials on them.

Q4: What’s the difference between a live load and a dead load?

People, tools, and materials are all part of the live load. Dead load is the weight of the scaffold itself.

Q5: How often should you check the load capability of the scaffold?

Before each shift, after bad weather, and any time the scaffold is moved or changed.

Q6: Who is in charge of making sure that the scaffold is safe?

Employers, site supervisors, and scaffold inspectors who are competent all share responsibilities.

Conclusion: Making sure that workers are safe when using scaffolding

The maximum load for a scaffold isn’t simply a number; it’s a very important safety aspect that might mean the difference between life and death. Workers and contractors can make sure the workplace is safe by knowing load ratings, following OSHA or international regulations, calculating loads correctly, and avoiding frequent mistakes.

One of the most trustworthy instruments in building is a scaffold that is well-maintained and used within its limits. But if you put too much weight on it, it might be dangerous. Partnering with a reliable manufacturer like GOWE SCAFFOLDING ensures you have equipment designed with safety as the top priority. Always follow the load limitations, check the scaffolds and teach your staff how to use them safely.