Building Connection Across the Strait

The Xiamen–Kinmen Bridge, one of China’s most ambitious cross-sea bridge projects, symbolizes connection and engineering excellence. Spanning the Taiwan Strait, this bridge faced complex marine conditions, high wind loads, and strict quality requirements for its concrete surfaces.

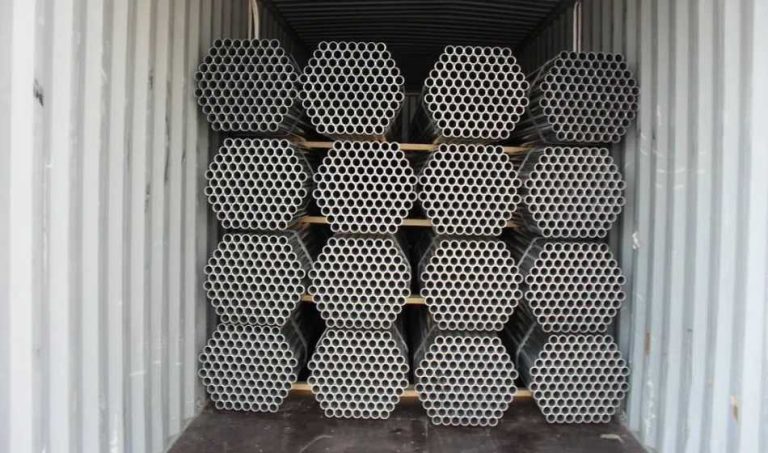

To meet these challenges, GOWE supplied a complete set of custom-designed steel formwork systems, along with full technical support — ensuring precision, efficiency, and durability throughout the project.

Project Overview

Located in the Zhangzhou Development Zone, the bridge’s pier prefabrication yard covers 183,000 m², the largest cross-sea pier prefabrication base in China.

The site was responsible for producing 87 prefabricated piers and 187 pier components within just 20 months, requiring exceptional accuracy, surface finish, and construction speed.

GOWE’s Technical Solution

Marine bridge construction demands formwork systems that resist corrosion, deformation, and misalignment. GOWE’s engineering team developed a tailor-made formwork design optimized for the bridge’s large span and variable cross-sections.

Key technical highlights include:

-

3D precision modeling to ensure every curvature and embedded part matched site geometry.

-

High-strength steel panels with optimized rib structures to reduce self-weight and maintain rigidity.

-

Anti-corrosion coating for long-term exposure to wind and seawater.

-

Custom connection systems to achieve tight joint control and smooth concrete surfaces after stripping.

One milestone achievement was the No.33 cap beam formwork, measuring 13 m high and 33 m wide — the largest and most complex mold used in the project, demonstrating GOWE’s advanced manufacturing capacity.

Full Project Support

Beyond product delivery, GOWE provided end-to-end technical service, including:

-

Real-time production and shipping updates.

-

Professional transport and installation guidance.

-

On-site engineers offering 24/7 technical support.

This full-lifecycle service ensured high construction efficiency, minimal downtime, and consistent quality — even under challenging weather conditions.

Results and Impact

The collaboration helped deliver outstanding concrete finish quality and improved project efficiency. GOWE’s solutions reduced rework time, enhanced precision, and contributed to the bridge’s structural durability.

The Xiamen–Kinmen Bridge now stands as a benchmark for modern cross-sea infrastructure, reflecting how advanced formwork engineering and craftsmanship can shape national landmarks.