Who It’s For: Project managers, site supervisors, and buyers who need safe and reliable scaffolding and aluminum formwork.

What You’ll Learn: Four common supplier traps and a simple five-step checklist to find a trusted partner.

Introduction

The 2025 Canton Fair is coming soon, and many buyers will head to Guangzhou to find new construction suppliers. The fair is always exciting — full of new products, fresh ideas, and good deals. But behind all the shiny booths, some suppliers still play old tricks.

If you’ve ever sourced scaffolding or aluminum formwork, you know how high the stakes are. The gear you buy must be strong, safe, and reliable. A small mistake in sourcing can turn into big trouble on-site—delays, repairs, and even safety issues.

After 15 years in this business, I’ve seen how one wrong choice can throw off an entire project. What is the good news? You can avoid most problems if you know what to look for. Let’s break down the four traps that catch buyers most often—and how experienced suppliers, like those you’ll meet at the Canton Fair, handle things differently.

Mistake #1: Going for the Lowest Price

Low prices look great on paper. But if a supplier’s quote is far below everyone else’s, something’s off.

They might use thinner steel, cheaper aluminum, or skip rust protection.

Here’s what usually happens:

- Equipment bends under normal load

- Rust shows up after a few uses

- You spend more time fixing and replacing parts

Cheap doesn’t mean smart. The best suppliers don’t just sell low prices — they sell lasting value. Quality materials and proper treatments help your gear last through many projects, saving you money in the long run.

Mistake #2: Believing Numbers Without Proof

Some salespeople throw around big claims—“50 kN per leg,” “200 uses per panel.” But without real test reports, those numbers mean nothing.

If you don’t check the facts, you might end up with:

- Formwork that fails under concrete pressure

- Scaffolding that doesn’t meet safety rules

- Lost time and added costs

Good suppliers prove what they say. They can show you test results, factory certifications, and quality checks. Some even invite you to see how they test materials. When a company takes the time to do that, you can tell they care about more than just sales.

Mistake #3: Buying from Suppliers Who Don’t Support You

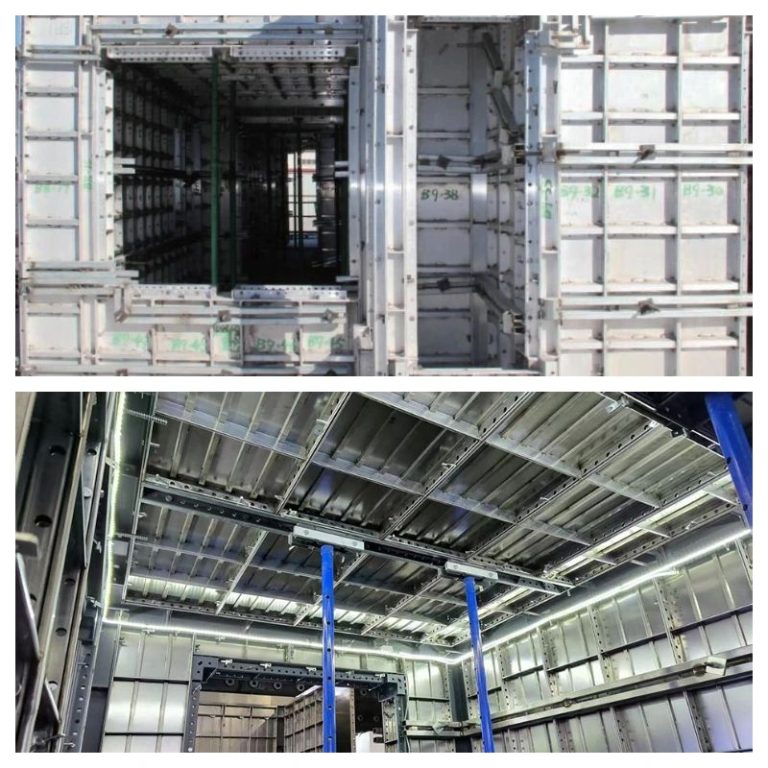

Scaffolding and formwork aren’t just metal parts — they’re systems. You need layout drawings, load data, and assembly guidance. But some suppliers only send products and leave you to figure out the rest.

That’s where problems start:

- Workers assemble systems incorrectly

- Projects fail safety checks

- You lose time trying to fix setups on site

Reliable suppliers act like partners. They help you plan your layout, check your loads, and make sure the system fits your project. A few well-established companies in China, such as GOWE, are known for offering this kind of engineering support—especially for large or complex builds.

Mistake #4: Ignoring Small Connection Parts

Everyone checks beams and panels, but few people inspect the small pieces—clamps, pins, and wedges. Those parts hold the entire system together. If a $2 pin breaks, you could face a major safety problem.

Here’s what happens when those parts are poor quality:

- Assembly slows down

- Connectors fail under stress

- Replacement costs pile up

Before buying, ask to see the connection parts. Hold them in your hand. Quality connectors feel solid and well-finished. Many top suppliers now make both the main components and connectors in-house to keep quality consistent—something worth checking during your supplier visits.

Your 5-Step Checklist for Choosing the Right Supplier

Step 1: Ask About Materials

Don’t just talk about price. Ask:

- “What’s your steel grade and wall thickness?”

- “What aluminum alloy do you use?”

- “Do you have certificates for the materials?”

Honest suppliers answer clearly and confidently.

Step 2: Check Certifications

Ask for ISO 9001 and EN standard test reports. If they can’t show them, that’s a red flag.

Step 3: Test Their Support

Give them some project details and ask for a layout drawing. See how quickly and clearly they respond. A good supplier’s engineering team will treat your questions seriously — even before you sign a deal.

Step 4: Inspect the Connection Parts

Ask to see samples of their clamps and pins. Feel the weight, check the finish, and ask about their warranty.

Step 5: Visit or Tour the Factory

If possible, visit their factory or ask for a video tour. Organized production lines, clear quality control steps, and trained workers tell you a lot about how they operate.

Suppliers with a strong reputation—including long-established Chinese manufacturers like GOWE, which runs advanced production bases in Tianjin, Guangdong, and Shandong — usually welcome visits. They know transparency builds trust.

The Bottom Line

Buying scaffolding and formwork isn’t just about getting materials—it’s about finding a partner who helps you build safely and efficiently. The right supplier saves you time, money, and stress. The wrong one creates problems that last the whole project.

When you walk the Canton Fair this year, look for companies that show proof, not promises—ones that offer technical help, transparent processes, and consistent quality. These are the suppliers worth building long-term relationships with. GOWE has more than 30 years of experience and has worked on thousands of construction projects in China and around the world.

If you find one like that, hold on to them. It can make all the difference between a project that runs smoothly and one that doesn’t.